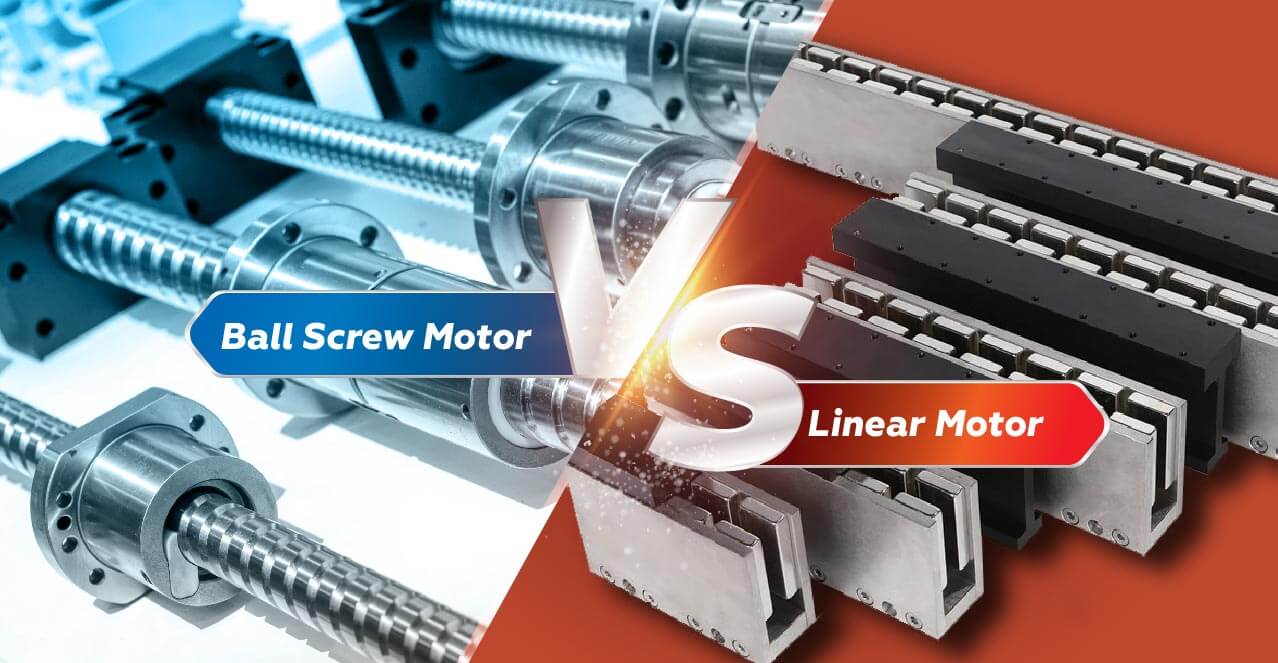

Linear Motor vs Ball Screw Motor: Selecting the Best for Precision Dispensing & Automation

Author: Wenjay Tew Wen Kiat, Last update on May 26, 2025, Prepared by the NSW Automation Marketing Team

In semiconductor, electronic manufacturing, automation and other industries, picking the right motor is crucial for good production quality and efficiency. Two popular choices in the industry are linear motors and servo motors (Ball Screw).

Linear motors vs ball screw motors; Each has distinct advantages to carter different aspects of manufacturing requirements and automation needs. The article explains these differences to help you make an informed decision tailored to your specific needs.

Linear Motor vs Ball Screw Motor: Comparison of Two Different Motors

Below are comparisons of the two motors. Take a look at the details to understand the differences between ball screw motors and linear motors, and find out which one is better suited for your specific needs.

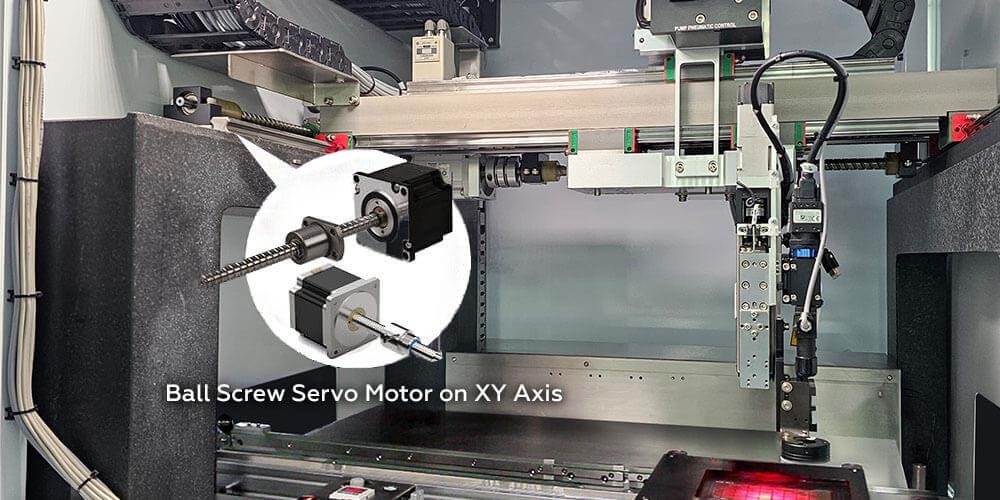

Ball Screw Servo Motors: Affordable and Reliable

Ball screw motors are a more budget-friendly option. They turn rotational motion into linear motion effectively and with acceptable accuracy for precision dispensing, suitable for many standard cost-sensitive tasks. They are not as fast as linear motors, but they are dependable and cost less, making them a good option for production where costs are a big issue.

These motors are also strong and can handle different manufacturing jobs well. They are especially useful where saving money is more important than having the fastest or most precise motor

For more info, refer to this comprehensive guide on ball screw motors.

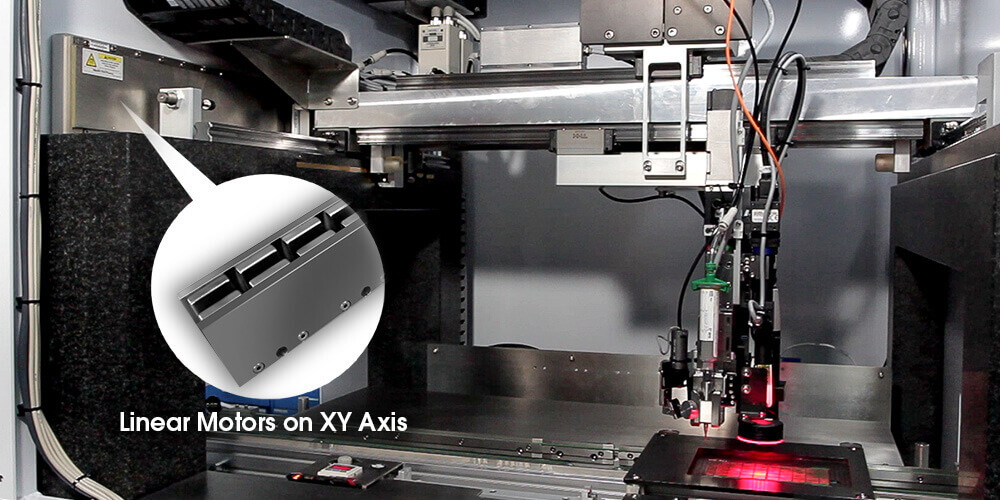

Linear Motors: Speed and Precision

Linear motors are great for fast and precise movements, which are important in making products quickly and accurately. These motors work with almost no mechanical wear and tear, they also need less maintenance. It is perfect for production that needs to keep running smoothly without a lot of maintenance downtime.

Linear motors are very precise and costly. They can detect and respond to movements typically having a resolution around 0.1 micrometers (µm). They are a good choice for jobs that need careful control, such as putting together micro electronic parts, medical devices manufacturing or other mission critical jobs.

Advantages and Disadvantages of Linear Motors & Ball Screw Servo Motors

Pros & Cons Comparison of Ball Screw Servo Motors

| Advantages | Disadvantages |

|---|---|

| Cost-Effective: Less expensive, making them accessible for cost-sensitive production. | Lower Speed: Not as fast as linear motors, which might limit production rate in some applications. |

| Easier to Set Up: Compared to linear motors, ball screw motors are simpler to configure. | Maintenance Required: Prone to wear and tear, especially in the screws and nuts, requiring regular maintenance. |

| Versatile: Can handle a wide range of loads and speeds, adaptable to various industrial needs. | Noise: Can be noisier than linear motors, which might be a consideration in certain environments. |

Pros & Cons Comparison of Linear Motors

| Advantages | Disadvantages |

|---|---|

| High Speed: Capable of very fast movements, which increase production speed. | Higher Cost: More expensive than ball screw motors, might not be feasible for all budgets. |

| High Precision: Provides very accurate control, essential for tasks where precision is mission critical. | Complexity: Might require more sophisticated motion control systems to manage the high precision and speed. |

| Low Maintenance: No gears or other mechanical components that wear out, causing constant part replacement. | Heat Generation: Can generate significant amounts of heat during operation, potentially requiring additional cooling systems. |

| Direct Drive: Eliminates the need for mechanical linkages such as gears, belt energy transfer system. It reduces energy losses and improves reliability. | Installation: May require more technical knowledge to align its precision and installation compared to simpler systems. |

The above tables compare both motors, showing their strengths and limitations to help you choose.

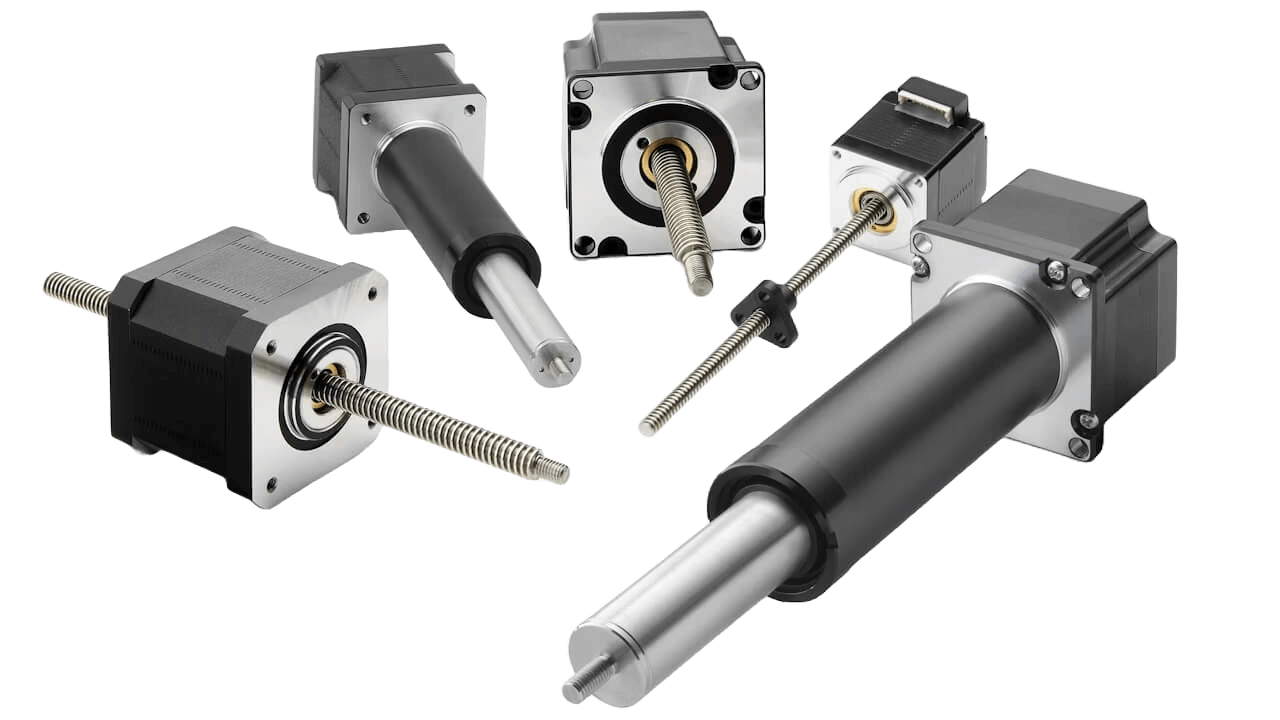

Photos above show both types of motors. At left, a linear motor. Right, ball screw servo motor.

Drag Here

Drag Here

A draggable Web Interactive showed comparison of 2 different motors on the same platform.

Linear or Ball Screw Motor: How to choose the right motor for your projects?

Choosing between a linear motor and a ball screw servo motor depends on what you need for your production:

- Speed and Accuracy: If you need very fast and precise movements, go for linear motors.

- Cost concert: If you are watching your budget, ball screw motors are a good choice because they are less expensive.

- Maintenance: Linear motors usually need less maintenance, which can save money and time in the long investment.

- High Precision: If extreme accuracy is the only concern, linear motors equipped with linear encoder is the only choice.

Linear Motor vs Ball Screw Motor: Conclusion

Your specific requirements will determine whether a linear motor or ball screw motor is the right choice for you..

For tasks that demand high speed and precision, and where cost is not the main concern, a linear motor is ideal. Conversely, if budget constraints are more critical while maintaining a reliable performance, a ball screw motor is more suitable.

Spend some time examining your production needs. Choosing the right motor will streamline the manufacturing process, enhance output quality, and boost overall efficiency, thereby making your organization more productive.

Contact NSW Automation for more info

For more information on precision dispensing equipment or if you have any micro-dispensing application needs, contact NSW Automation. Our team of experts is ready to assist you in finding the best solutions tailored to your specific requirements.

We offer comprehensive consultations to ensure you get the most suitable equipment for your projects and manufacturing needs. For further details and consultation, contact us here.