How Agitators Help Overcome Sedimentation in LED Phosphor Dispensing

Author: Tan Yi Farn, Last update on May 26, 2025, Prepared by the NSW Automation Marketing Team

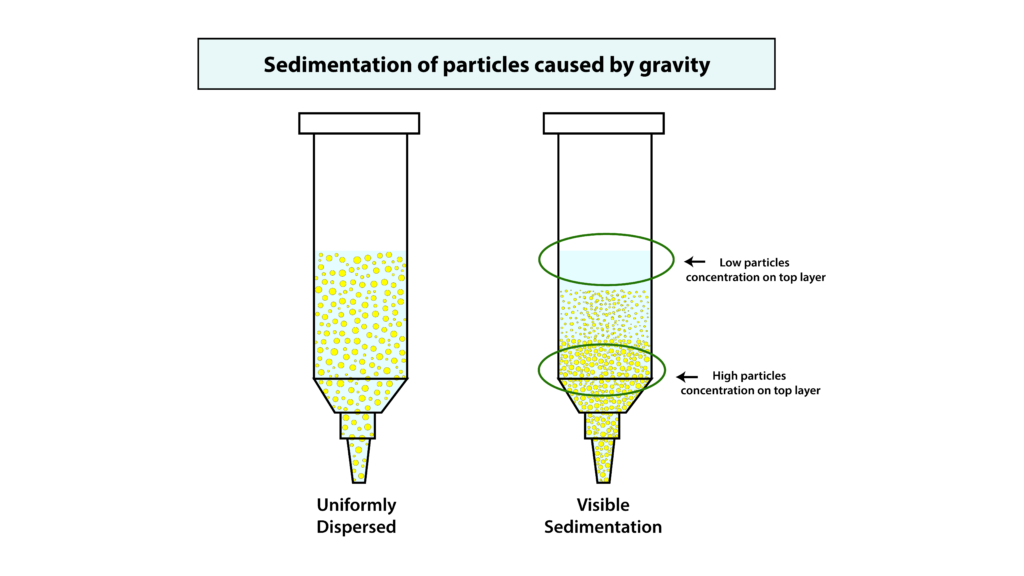

What is Sedimentation?

In LED phosphor dispensing, sedimentation can lead to inconsistent quality and inefficiency. Sedimentation refers to the settling of solid particles, like phosphor, within a liquid medium due to gravity. In dispensing systems, this causes heavier phosphor particles to settle at the bottom of the syringe, leading to inconsistent material flow.

Why Does Sedimentation Happen?

Phosphor materials are inherently high in viscosity. Without continuous agitation, particles settle over time, this foundational issue cascades into several other challenges:

1. Colour Mismatches

Cause: Uneven layer thickness results in varying phosphor concentration.

Impact: The inconsistent conversion of blue light causes visible colour discrepancies, compromising LED performance.

2. Production Disruptions

Cause: Settling phosphor particles clog dispensing nozzles.

Impact: Increased maintenance and downtime drive up production costs.

The Solution: NSW Automation’s Agitation Systems

Our agitation systems prevent sedimentation by keeping phosphor materials evenly suspended, ensuring consistent dispensing and reliable production.

Key Features of Our Agitation Systems

PistonPRO 4+ with AgitaFlow

1. Customizable Rotation Control:

Clockwise and counterclockwise mixing prevents particle settling.

2. Precise Time Interval Setting:

Fine-tuned agitation cycles maintain uniform suspension.

3. Seamless Integration:

Compatible with all NSW dispenser platforms for versatile applications.

Why Choose Us for Your LED Solution?

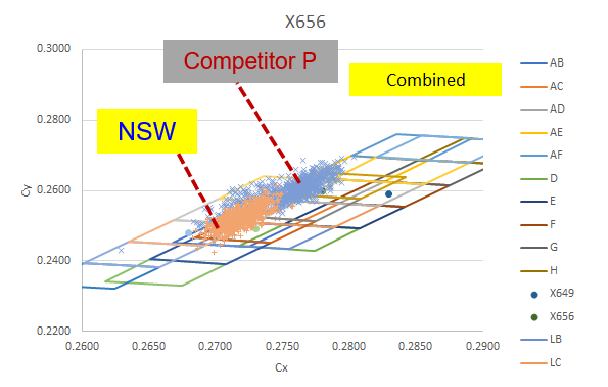

- 25% Better Consistency*

- 30% More Precise Color Uniformity*

- Eliminates Material Sedimentation

- Fully Programmable & Customizable

- Handles Low Viscosity Materials

- Prevents Pump Clogging

*Based on CIE result data & reports

By integrating our agitation systems, manufacturers achieve:

- Superior LED Quality

Consistent phosphor layers ensure accurate colour and uniform light emission.

- Improved Productivity

Reduced downtime and maintenance boost efficiency and throughput.

- Adaptable Performance

Suitable for various phosphor materials and applications.

Our Involvement in Led Industry

Regular LED

- SMD LED

- Display Device

- Side Mount LED

Advanced LED

- COB LED

- CSP LED

- Flip Chip LED

Emerging LED

- OLED

- MINI/Micro LED

- Pixel cell LED

Specialize LED

- High Power LED

- UV LED

- WL-LED

Conclusion

Preventing sedimentation is critical to maintaining consistent particles layers, which are essential for achieving accurate colour, uniform light emission, and smooth production processes.

Elevate Your Manufacturing with us!

Contact us today to learn how we can support your production needs.

1. IDENTIFY YOUR PRODUCT/PROCESS

Workpiece

• Leadframe

• Wafer

• PCB

2. CONFIGURE YOUR DISPENSING SOLUTIONS

Equipments + Pump & Valve

3. POST-DISPENSING SOLUTIONS

Customization

• AOI Check

• Phosphor Height Scan

• Robotic Handler

• Equipment Integration