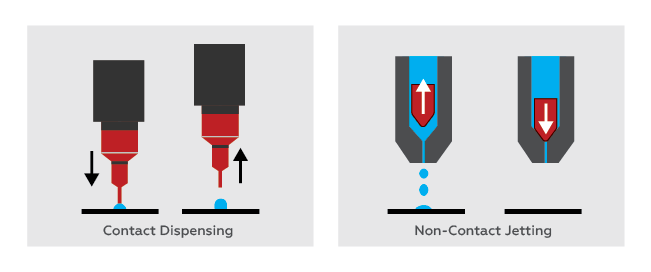

Contact Dispensing and Non-Contact Jetting

Author: Wenjay Tew Wen Kiat, Last update on March 14, 2025, Prepared by the NSW Automation Marketing Team

Why Choose Contact Dispensing Over Fluid Jetting When Miniaturizing Modern Electronics?

Do you know the secret of why most Semiconductor, SMD Manufacturing professionals prefer contact dispensing over fluid jetting for precise micro dispensing applications such as wafer-level packaging, 008004 solderings, 01005 dispensing, PoP, SiP, 3D-mid jobs? In this article, we’ll be discussing the advantage of contact dispensing and non-contact dispensing (Jetting).

Well, to illustrate our point, here is an exciting story about effectively getting a ball in a very small tight area. It depicts a scenario of why contact dispensing wins over the other.

Throwing vs placing a ball: Contact dispensing and non-contact dispensing

Let’s use this example: Peter wants to put a ball in a tiny and narrow targeted area. He has two choices. He can either:

Placing (Contact Dispensing)

Move over to the targeted area and place the ball at its designated place.

Throwing (Jetting – Non-Contact Dispensing)

Throw the ball from a distance and hope it will land it in that very small and narrow spot— perfectly.

When comparing these two scenarios of throwing and placing, which one should Peter do for the best accurate result? Surely placing would be the best option. It is the most effective headache-free solution. There will not be any worries of misplacements or imprecision.

What if you were to throw many balls at a fast speed, what would the percentage of accuracy be?

It is the same with dispensing. Jetting is throwing while contact dispensing is placing.

While jetting (throwing) can be rapid in quickening production, contact dispensing (placing) is highly accurate and precise but slightly slower in speed. It enables the possibility to dispense smaller droplets. For this reason, contact dispensing is highly suitable for high-value products with uneven topographies, deep cavities, and dense holes.

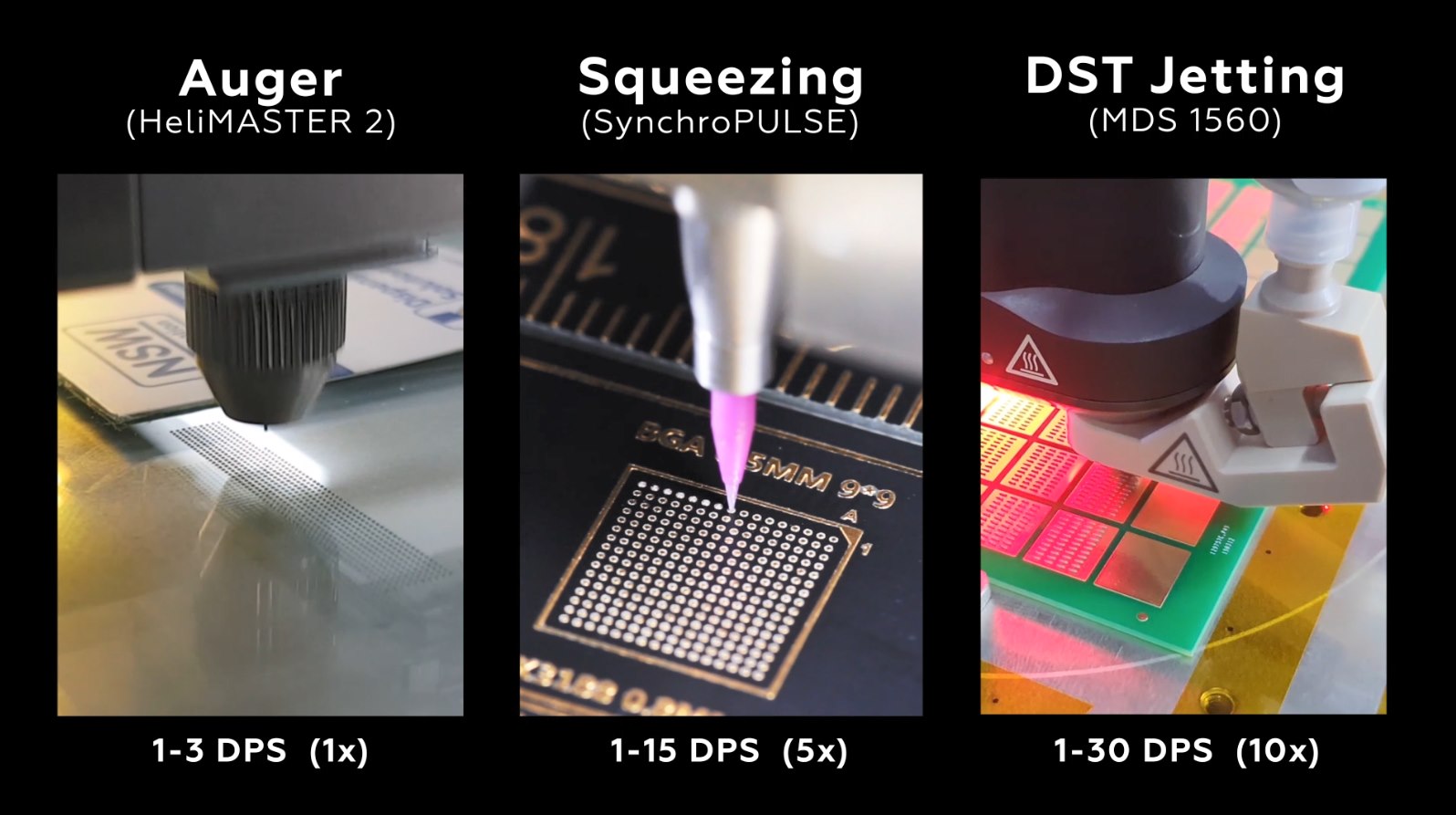

In the video above, left and center: contact dispensing, right: non-contact jetting.

Advantages of Both Jetting and Contact Dispensing

Let’s take a closer look at both the advantages of jetting and contact dispensing methods. In this study, we have included some in-depth characteristic review of each approach.

List of Advantages of contact microdispensing (placing):

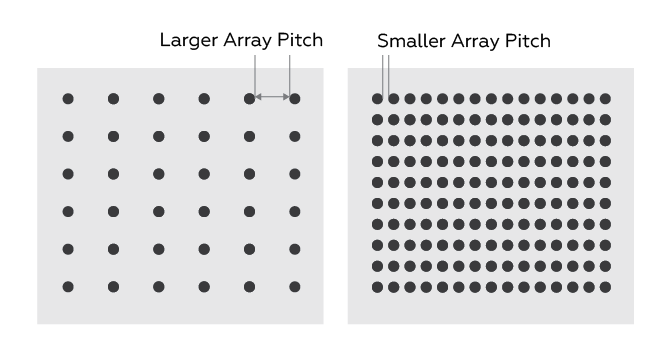

- Denser Droplets Pitch – Spaces between each droplet can be squeezed to provide a compact array pitch. It is capable of creating an array of dots and lines (e.g. ball grid array) with closer spacing tighter with each other. This means smaller footprints for each dot and line.

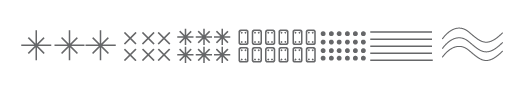

- Dynamic Lines and Artful Shaping – More agile and flexible in dispensing pattern formations. It is capable of plotting a variety of complex applications and device packaging such as wafer-level dispensing, 01005 solderings, 008004 dispensing, PoP, 3D-MID. Microcontact dispensing capabilities consist of multiple dynamic shapes/pattern dispensing such as curve lines, asterisks, spiral, double-crosses, boxes, and circles. (refer image below)

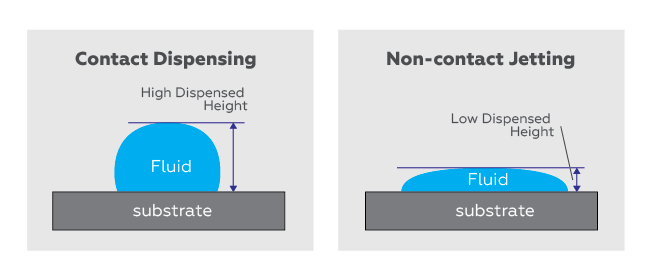

- Create Higher Droplets Heights – Able to build higher droplets height with the same volume. When applying directly on surfaces, it can make fluid droplets taller by “pulling” and controlling dispensations towards your desired height. This makes the fluid droplets taller in height. It has a higher “HoW” (Height over Width) ratio rate for the same droplet of liquid when being dispensed by a non-contact jet. This greatly benefits applications such as wafer bumping, substrate pumping, solder paste bumping and epoxy damming.

- Less Wear and Tear – Microdispensing placing does not require consistent vigorous moving of internal parts as compared to jetting. Jetting requires machinery to work at extreme speed with continual repetition, causing damage after a period of time.

- No Satellites issue – Satellites are unwanted splashes made when droplets collide against the product surface. Placing solves this problem so dispenses are always neat and tidy.

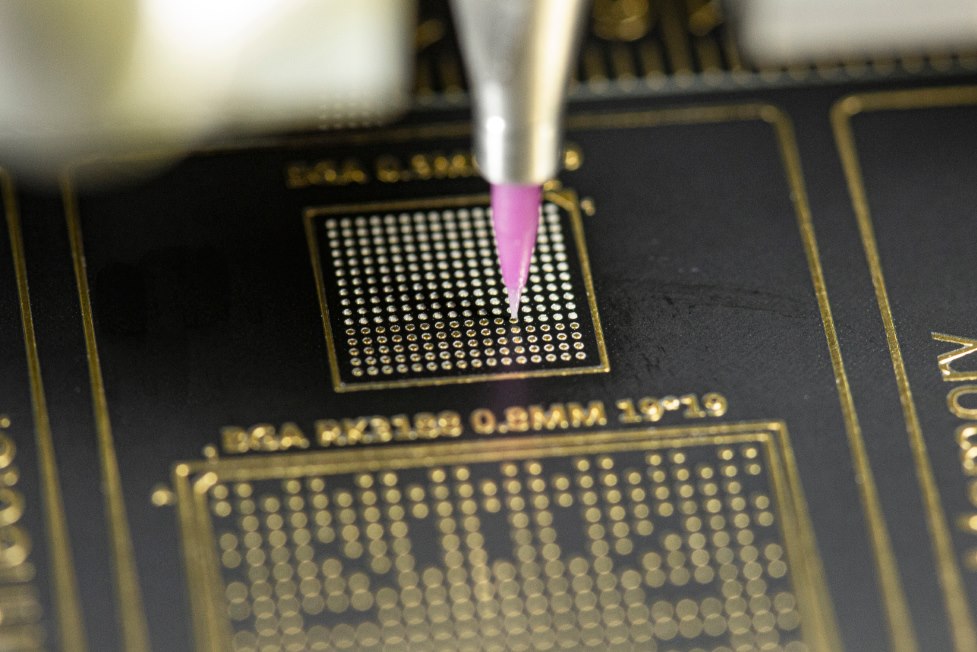

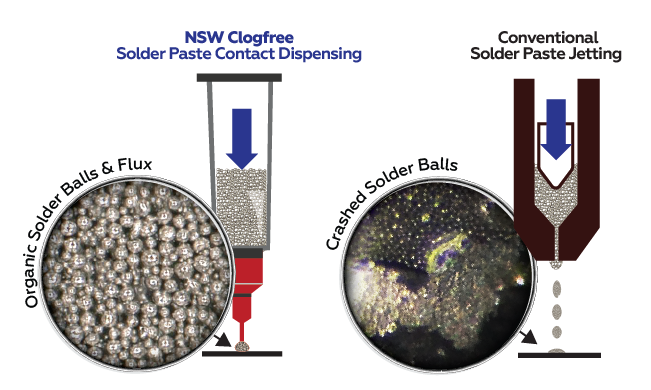

- Suitable for Particle-Filled Fluids – Fluids such as solder paste are tricky to jet. Dissimilarity, placing can easily perform microdispensing of solder paste without crushing or deforming solder balls with our latest NSW SynchroPULSE contact dispensing pump heads.

- Finer droplets/lines & Smaller Dispensing Volume – Contact microdispensing can disburse microscopic fluid volume at a very low microliter. It is suitable for applications such as 008004 soldering or 01005 dispensing. There are no physical limitations to dispense minuscule liquid droplets hence tiny volume dispensing applications smaller than 200μm are easily achievable. It’s difficult to dispense micro lines (size below 200μm) in a single cycle when via jetting. Its spray distance to the surface of the product is not ideal. Contact microdispensing solves this because its needle tip can draw closer to the product facet, allowing better consistency and control.

- Angled Trench/Cavity Capability – Able to dispense at angled positions into tight dense holes or cavity walls. Placement methods are suitable for production applications such as 3D-MID, PoP, SiP. In certain cases, high-density deep cavities and complex SMD boards may not be feasible with jetting due to its jetting distance.

- Lower Cost – Since placement has lesser wear and tear issues, part replacements are also significantly reduced. This helps lower maintenance and purchasing costing.

- Better Accuracy – Placing utilizes z-axis motion for droplets dispensing. This extra axis provides finer precision degrees compared to jetting.

- Lower Noise – Compared with jetting, contact microdispensing works quietly and has no annoying high pitch noise.

List of Advantages of non-contact jetting (Throwing):

- Swift Liquid Distributions – Fluids are applied with faster speed compared to placing methods. It does not have z-axis motions when dispensing liquid. Its jet head motion only focuses on x or y-axis when distributing liquid—resulting in faster-dispensing rates. Speed (droplets per second) could reach as fast as 3000hz with epoxy or 50hz with solder paste.

- Time-saving – Production time is significantly reduced through the ejection of liquid onto products at a higher speed.

- No needle tip damage – Jetting is a non-contact dispensing fluid application. Fluids are applied without touch (physical contact). Hence there’s no risk of costly broken needle tips which could cause downtime for parts replacement.

- Non-contact dispensing operation – Jetting prevents damages to fragile products as there is no physical contact during its application process. With its “drop on fly” dispensing method, its non-touch system avoids damages against sensitive substrates.

- Surface Topographies – Since there are no z-axis motions, jetting is capable of rapidly applying fluid to surfaces with different topographies at accelerated speed compared to contact jetting. Unlike contact dispensing, there is no necessity to spend avoidable time to scan for height differences before the dispensing process begins.

Furthermore, needle tip residuals and air variation could affect dispensing performance and deposit repeatability on both non-contact jetting and contact dispensing. With the use of NSW in-house master-crafted needle tips, residual materials are less likely to clot fluid outlets.

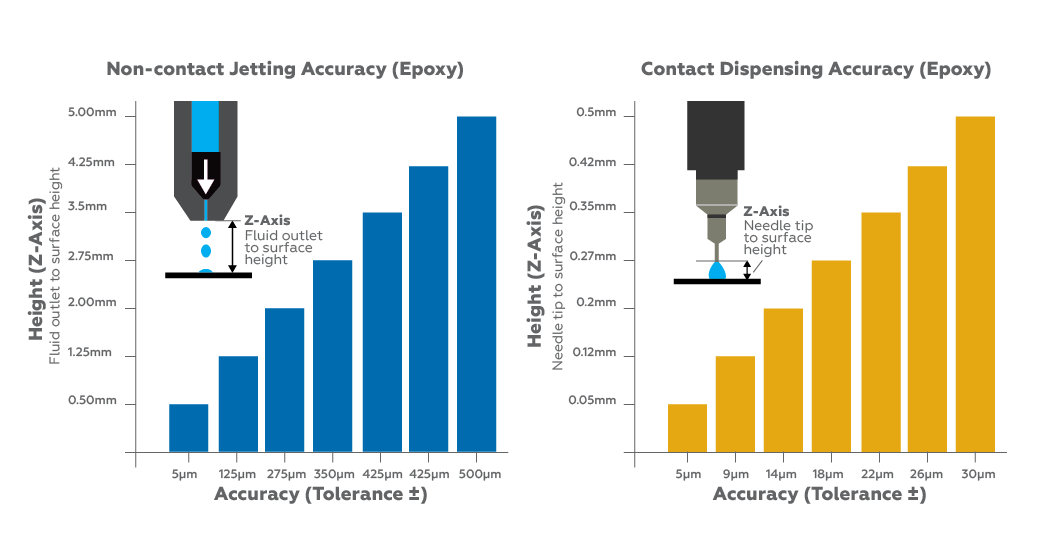

Jetting Drawback: Accuracy Decreases If Distance of Z-Axis Height Increases.

Microdispensing precisions could be negatively affected due to fluids being “thrown” (jet) at a high distance between the liquid outlet and its target. Besides that, fluids that are being applied “on the fly” happens at extremely high speed. It could be as fast as 3000 Hz (droplets per second), hence reducing dispensing accuracy.

- Jet dispensing’s z-axis ranges from a distance of 0.5mm to 5mm during production operations.

- Contact micro-dispensing applications operate with “placing” methods at 0.05mm to 0.5mm from needle tip to target surface.

These Z-axis values are determined by material properties. Certain material allows greater distances while others require lower Z-axis ranges.

Disclaimer: Data shown in the chart is according to our in-house performance test results. Dispensing results and performance are subjected to material characteristics and properties. Different materials require different dispensing methods. Please contact your material supplier for compatibility enquiries.

Which Situation Would Be Best For Contact Dispensing?

NSW Automation proudly specializes in contact dispensing that you can trust. Since contact dispensing has Z-axis motion features, it allows the needle tip to come close to the product surface for fluid dispensation. This added advantage enables the dispense capabilities of micro-droplets sized below 100μm, suitable for applications such as MEMS, 008004 component, Sip, Pop or complex miniaturized application.

Using the contact dispensing approach, (such as NSW SynchroPULSE and PistonPRO 4+ fluid pumps) our system dispenses without splashing and significantly reduces deposit satellites in acceptable tolerances. Besides that, our superior dynamic fluid volume control enables the possibility of ejecting dynamic fluid volumes within each dispensing cycle. This feature allows you to dispense a wide range of layout patterns on microscopic packages.

Can Jetting Dispense Micro Solder Paste Droplets Effectively?

In contrast to placing (contact dispensing), jetting saves time as it has higher dispensing speed properties. Its drawbacks are its infeasibility to flawlessly jet highly-abrasive fluids and particle-filled materials such as solder paste at microscopic volume. Jet dispensing is generally used to dispense silver epoxy, adhesive and encapsulant underfill for flip chips or other applications which are not sensitive to accuracy and droplets volume.

So is non-contact jetting or contact dispensing better for me?

With massive demands, today’s electronic devices are gradually shrinking day by day. The industry now requires smaller manufacturing capabilities as new varieties of materials emerge. There are huge demands for microscopic dispensations with greater accuracy and consistency requirements.

For instance, complex high-value microscopic dispensing applications such as 008004 solderings, 01005 dispensing, MEMS, 3D-mid soldering, SiP, PoP require tinier fluid droplets to be applied. These challenging applications are easily achievable with our latest NSW SynchroPULSE pump heads.

Alternatively, jetting has the advantage of high production speed and lower time cost. However, its limitations are its accuracy on microscopic dispensation (100μm or below) as it may not be able to perform as precisely as contact dispensing.

The verdict is that since there are a lot of factors to consider, we are unable to conclude which is eventually the best method for your dispensing application.

Ultimately, both non-contact jetting or contact dispensing performances are subjected to the characteristics and suitability of your materials. However, we highly suggest the use of contact dispensing for microscopic high-value products, if high production speed is not a concern.

[Fancy_Facebook_Comments]