Why We Need Micro-volume Solder Paste Dispensing?

Author: KC Tai, Wenjay Tew Wen Kiat, Last update on March 14, 2025, Prepared by the NSW Automation Marketing Team

Facilitate Smaller SMD Manufacturing Capability with Tiny Volume Solder Paste Dispensing Technology.

In the era of complex Industry 4.0, Artificial Intelligence (AI), Internet of Things (IoT) and 5G. These Smart Digitalization and data industries enhance the globally fast-growing of smaller advanced microelectronics for the packaging market. We need to find a new way to dispense into a smaller component with complicated heterogeneous design, this is why we need low volume solder paste dispensing capability.

Unfortunately, huge challenges are found on the packaging miniaturization processes such as 008004 capacitor especially the fluid material handling portion. Neither a conventional screen-printing method nor a common dispensing process could feasibly transfer an exact amount of ultra-fine dots or lines onto a complex tiny package accurately and consistently.

Therefore, to achieve the capability of low volume transfer of solder paste into a challenging area of a tiny package. Our Revolutionized Micro-volume Solder Paste Contact Dispensing Technology is used to dispense an exact amount of liquid into a tiny area with gaps and uneven surface at precise volume. This enabling better accuracy for a complex and high-value product such as 5G optical component or complex 008004 capacitor. It can also use for other packaging miniaturization market which is infeasible with normal dispensing equipment.

World’s Smallest capacitor – 008004 Size (0.25 x 0.125 mm) enables the opportunity for the use of microdispensing.

It Let You Breakthrough Your New Product Development Threshold, Redefines All-new Milestones

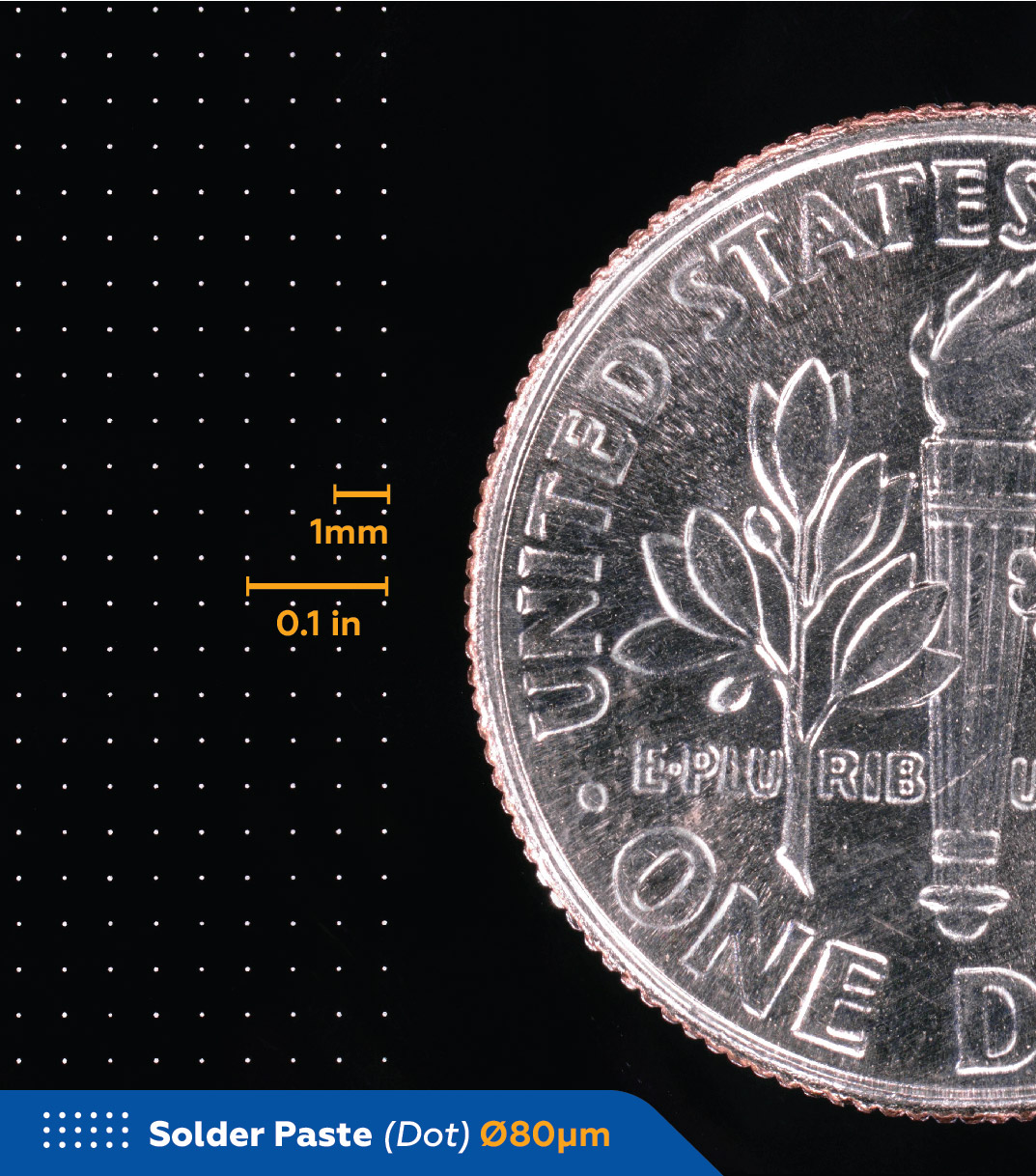

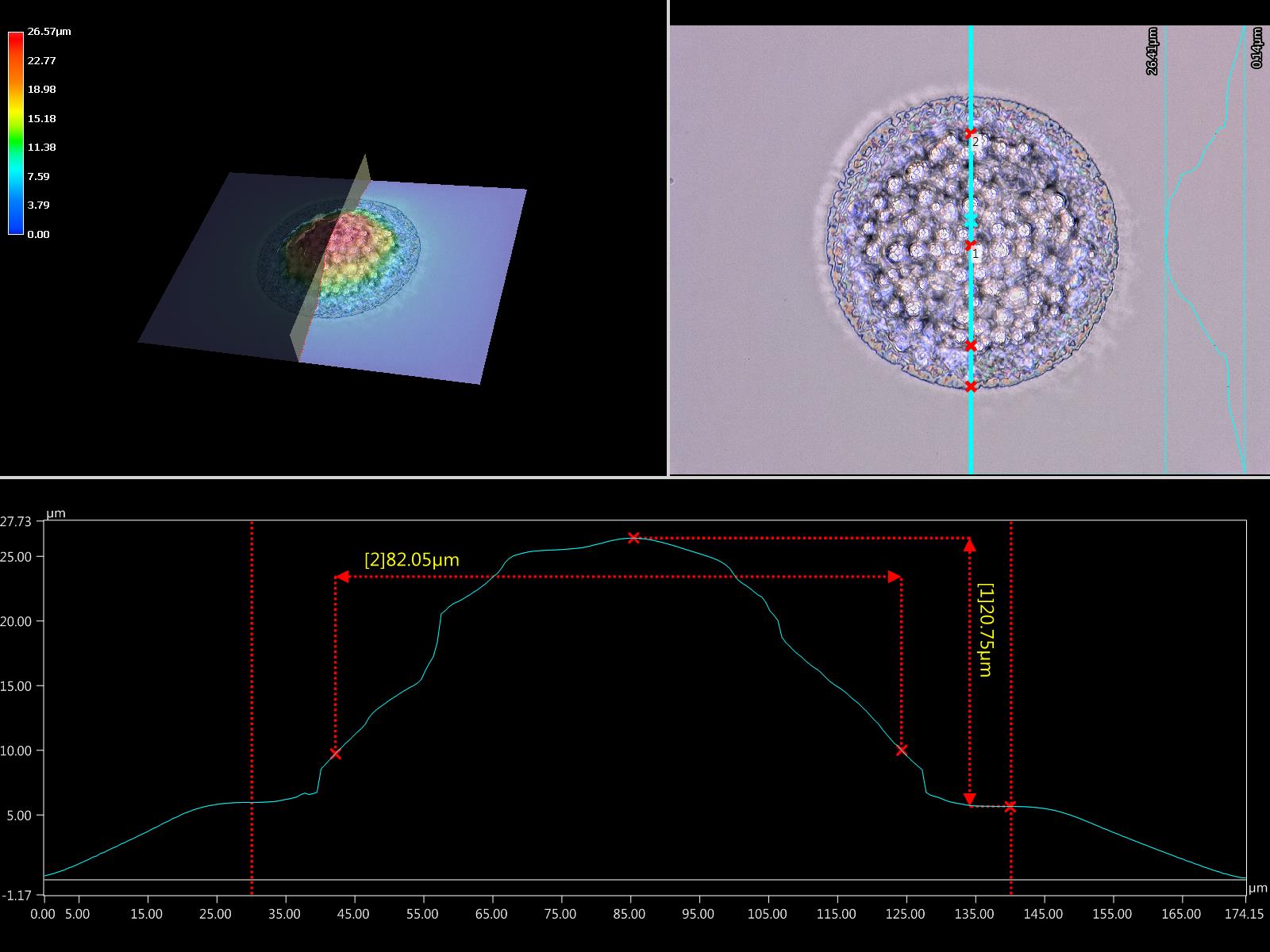

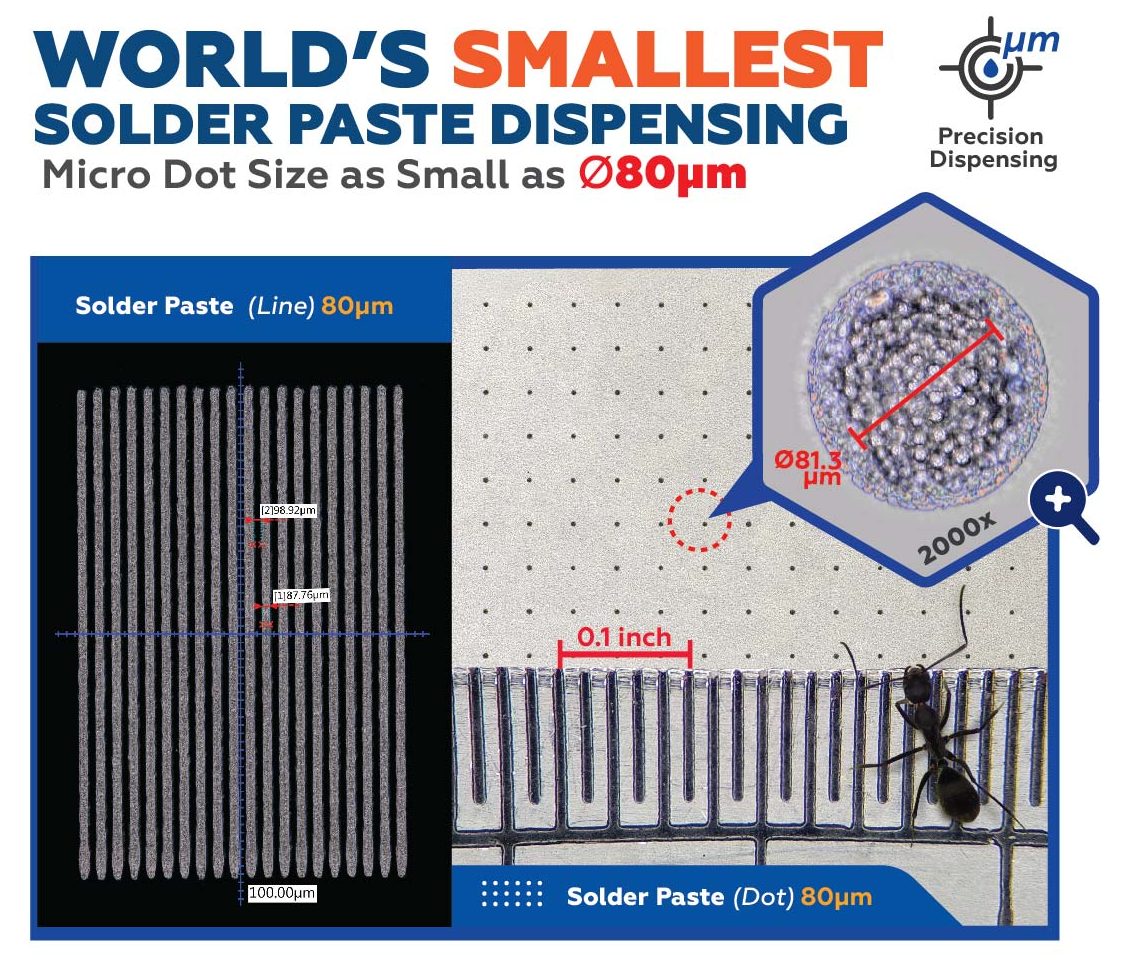

NSW Automation is globally recognized precision fluid dispensing equipment’s ODM and OEM supplier, our famous invention and unique Solder Paste Micro-Dispensing Technology has achieved the smallest solder paste dispensed volume in the world with size as small as Ø80µm (dots diameter and micro lines) via industry-standard Type-6 solder paste.

Image above shown detailed magnification examines and measurement of dispensed type-6 solder paste microdots.

The Key for Enabling Your Solder Paste Micro-dispensing Work as Small as 80µm, What’s Special Behind It?

The beauty of our solder paste micro-dispenser is to help you to dispense onto your miniaturized microscopic products without crushing or deforming the solder balls in the dispenser. Additionally, our unique dispensing mechanism could probably avoid certain flux separation issues due to environment conditions uncertainty like fluctuation of humidity, temperature level.

Other than the micro-dispenser pump head, a perfect combination of a reliable dispensing handler integrated with NSW designated precision motion platform is another huge know-how topic to support and optimum our great micro-dispensing achievements.

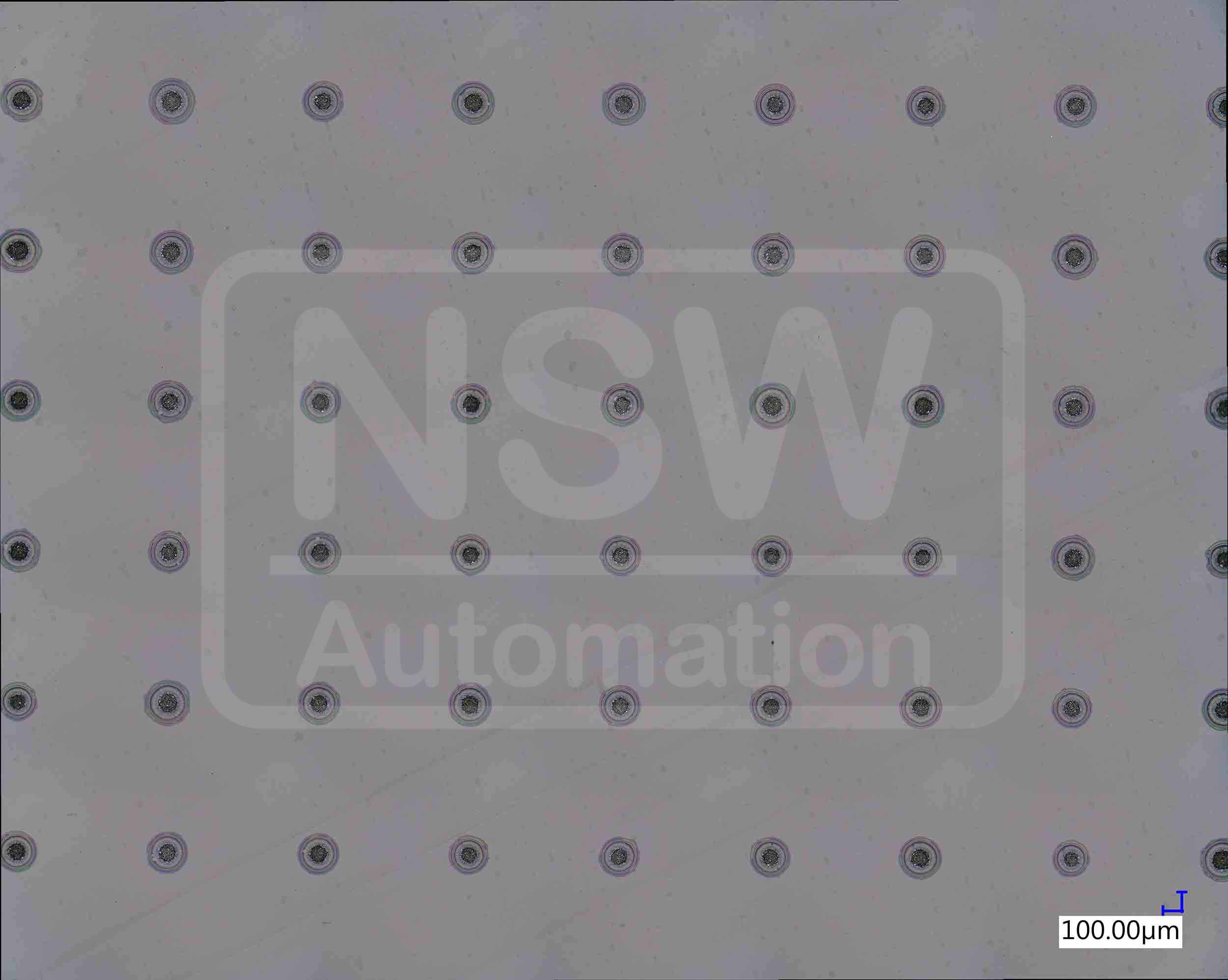

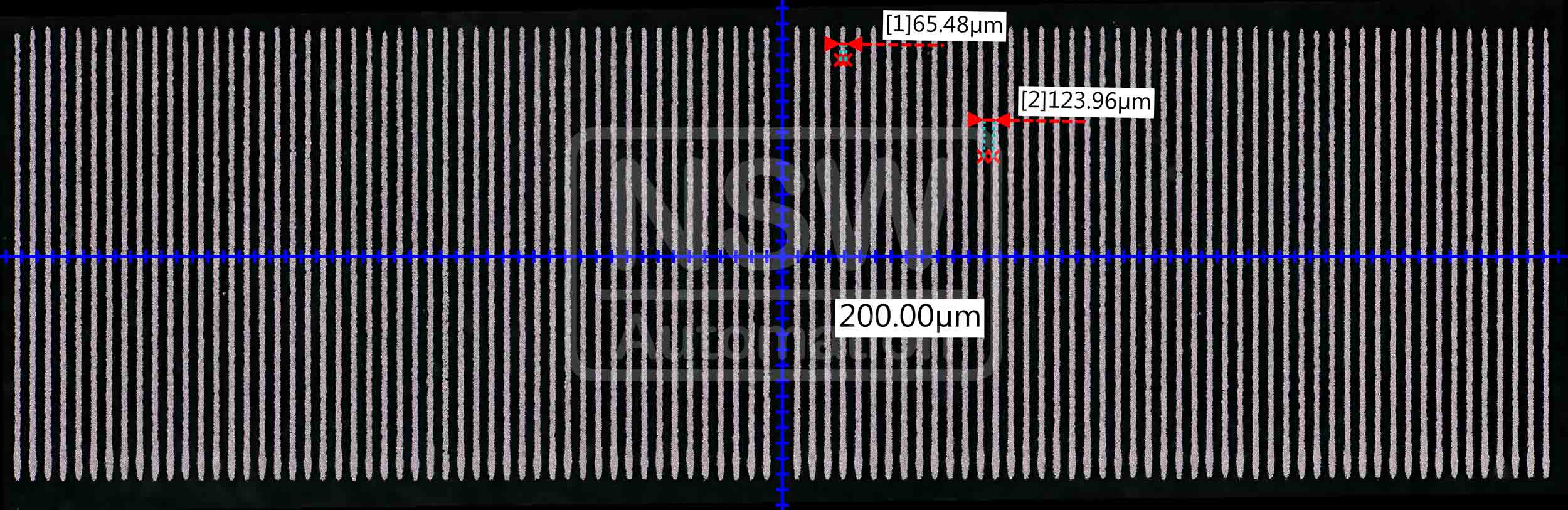

Images above shown diameter and linewidth measurement of dispensed type-6 solder paste microdots and lines.

How about other materials? Can they handle challenges?

On top of that, our micro-dispenser could also support others’ micro-dispense materials like fluxes, conductive silver epoxies and UV adhesive etc. We have another breakthrough in non-filler and Nano-filler material dispensing as tiny as 40µm size. Commonly this is an extremely infeasible mission for conventional dispensing equipment to realize it.

Want to know more? Download our white paper!

You may also view and download our report here. For more info on our application and solutions visit here.

If you are ready to learn more about our micro-dispensing technical details and products, kindly contact us now!

[Fancy_Facebook_Comments]