How to Prevent Solder Paste Dispensing Clog Issues

Author: Wenjay Tew Wen Kiat, Last update on March 14, 2025, Prepared by the NSW Automation Marketing Team

Best Practice and Tips to Prevent Solder Paste Dispensing Clogging issues.

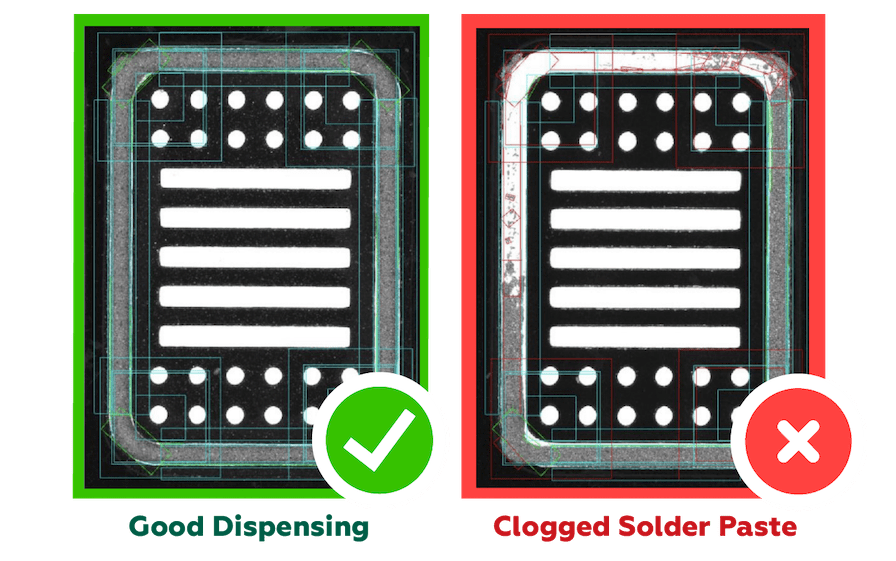

How do you prevent solder paste dispensing clog, blockage or choke? As the dispensing industry continues to grow, there has been a demand for intelligent, innovative new ideas to make dispensing easier. However, one of the major problems with solder paste dispensing is clogged or jammed dispensing valves.

Adhesive dispensing systems constantly process dispensing applications with fluids like solder paste, epoxies, and other types of adhesives. When dealing with such materials and maintaining control of repeatable, accurate, and measurable results, it is essential to upkeep your dispensing systems properly to avoid potential clog problems.

What are the top issues that dispensing equipment operators usually deal with? Here are some situations we often hear from industry players. You may be familiar with some of these issues too:

1. Loss of Yield and Unwanted Downtime Due to Clogged Nozzles

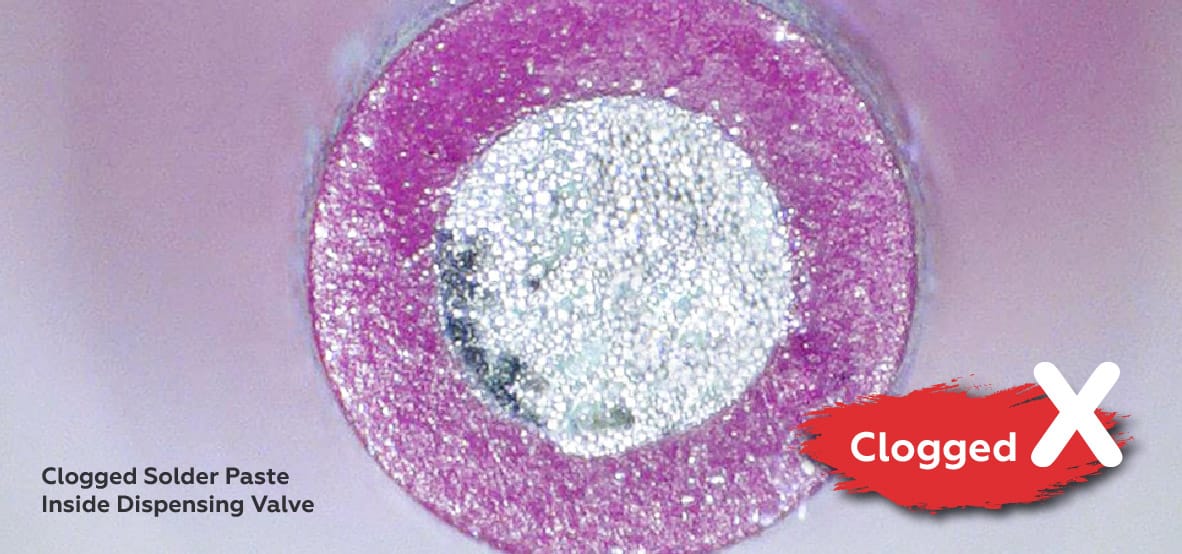

Under normal conditions, a dispensing valve can handle a wide range of viscosities, but if the viscosity increases past a certain threshold, the valve tends to clog. Not only is it an inconvenient hassle, but operators also need to spend time to change and clean the clogged nozzle. The whole operation is halted as you need to set up the machine to re-run the process again. Such downtime can hamper your efficiency and production.

2. Clog Time Can Be Tiresome and Costly

What are other losses besides production efficiency and volume of output? You would also spend unnecessarily on replacement nozzles to gain optimized results. You cannot rely on a clogged nozzle for optimum yield. Not only that, but you also waste solder paste during the removal of material and cleaning process. It disrupts work cycles to clean the nozzle and valves so that work can continue.

3. Product Failure Due to Inconsistency

The last thing you would want to encounter a batch of products that are unsalable to the market. Tiny issues like clogged valves lead to big output problems causing product output to drop. It significantly lowers your UPH (Unit Per-Hour) productivity and quality output of your dispense operations, causing you to redo batches and productivity interruptions.

A clogged dispensing valve is a problem because it can cause the dispensing of a product to stop, which can be both frustrating and expensive. You certainly do not want to face such pointless downtime and potentially costly repairs.

So how to prevent dispensing clogging? To prevent fluid dispensing clogging problems, here are some of our before, during, and after best practices to help prevent dispensing clogging in your operations.

What to Do Before Dispensing to Prevent Blockages and Clogging?

For optimum dispensing outputs, it is best to prepare and check on certain conditions before you start. Here are some situations that you might want to take note of to prevent solder paste dispensing clog.

1. Use Dispensing Grade Solder Paste.

For best performance, use dispensing grade solder paste for dispensing process. Using non-dispensing grade solder pastes (like for stencil printing and reusing unused paste from other processes) may seem like a good idea to save cost, but however its quality may be questionable and may cause more harm than good. One of the major setbacks is inconsistency. This is due to tiny micro bubbles that jams up your nozzle – hindering smooth quality prints.

2. Storage Climate Stability.

Store fluid materials like solder paste at the proper temperature according to the manufacturer’s guidelines. It is best practice to store your materials in a cool room of <15 °C/ 59 °F or according to the recommended manufacturer’s advice.

3. Place the Solder Paste in a Tip-down Position.

This placement avoids separation between flux and solder ball.

4. Take Note of the Expiry Date of your Materials.

Surprisingly, many operators tend to overlook this vital factor. Expired material may have dried by the time you use it, causing unwanted clogging.

5. Pair the Right Nozzle to Solder Paste Type.

It is essential to pair the right nozzle according to the specific dispensing requirements. It is recommended to use type 5 solder paste and above for general dispensing. Solder paste types depend on the dispensing size requirements. (Refer below “Chart Figure 1.0” to understand more.)

Best Practices During Dispensing to Avoid Clogging Issues.

Now that we have covered what you can do during pre-dispensing, you have already prepared yourself for smooth dispensing. However, this does not mean that clogging will not happen after knowing what to do during the pre-dispensing period. Here are some of our recommended best practices are during the dispensing process to follow to ensure optimum no-clogging dispensing.

1. Nozzle Inner Diameter (ID)

Make sure to use nozzle ID that is at least 5x the solder particle size. Here is a chart below for your easy reference.

Note: Clogging issues might occur if you use smaller than recommended nozzle sizes. For accurate details please consult your dispensing nozzle manufacturer.

| wdt_ID | Type | Range (max-min) | Recommended Nozzle Size | Dispensed Size Range |

|---|---|---|---|---|

| 1 | Type 5 | 25–10 μm | 125 μm above | 150-200 μm |

| 2 | Type 6 | 15–5 μm | 80 μm above | 80-150 μm |

| 3 | Type 7 | 11–2 μm | 50 μm above | Below 80 μm |

| 4 | Type 8 | 8–2 μm | 50 μm above | Below 50 μm |

Chart Figure 1.0

2. Use Low Pressure When Dispensing

The mixture of solder paste is a combination of flux and solder paste. It is essential to keep the pressure low at this point because higher pressure may result in separation at the syringe, causing clogs to happen.

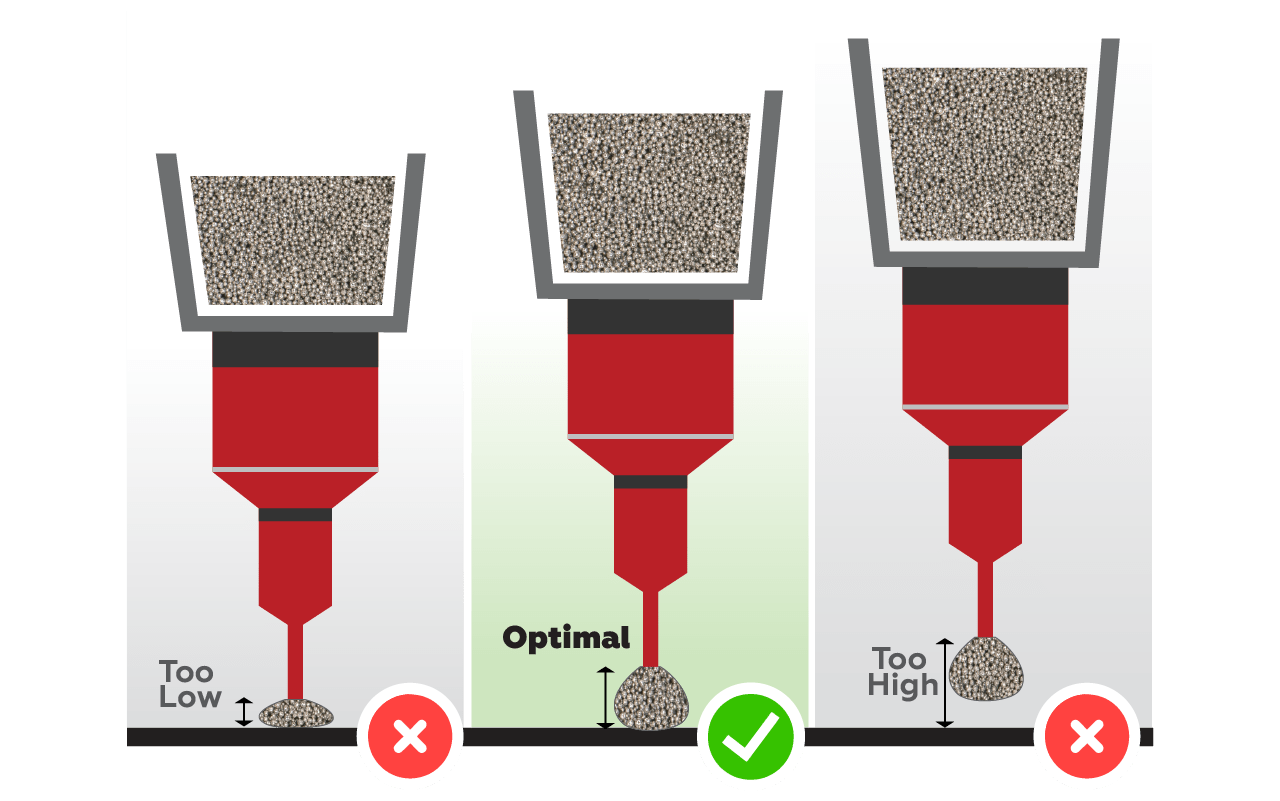

3. Go Low But Not Too Low (Z-Axis)

It is important to keep a suitable gap between your nozzle and workpiece surface. Operators who have exceptionally low gap settings often find themselves in a solder paste dispensing clogging situation. Low gaps trigger solder balls getting trapped in the nozzle resulting in clogging. Do not leave gaps too high as well. If you go too high, fluids will not stick on the surface of the workpiece you are dispensing on.

What to Do After Dispensing?

We have covered our best recommendations on our best practices during the dispensing process. However, what happens after that? The dispensing process is not over yet – at least if you want to prevent fluid dispensing clogging issues.

Here is our follow-up guide to avoid future dispensing clogging headaches.

NSW custom specialized nozzle cleaning tool.

i. Remove Excess Solder Paste and Seal Off Instantly After Use.

After a dispensing process is completed, it is best practice to remove the syringe and instantly seal the cap without delay. Store all left over solder paste at proper storage according to manufacturer guidelines at the recommended temperature.

ii. Cleaning Prevents Clogs.

Essentially, all nozzles must be thoroughly cleaned after use. Dirty nozzles with prior material residues significantly increase the chances of clogs. It is essential to clean all nozzles properly with a specialized nozzle cleaning tool. We recommend dipping the pump and nozzle at ultrasonic levels with IPA. This optimally removes all solders to ensure there is no more remanence in the nozzle.

iii. Use the Right Cleaning Tool.

With NSW’s next-gen cleaning tool, we ensure that your nozzles are always spick-and-span, ready for the next dispensing job.

NSW Equipment Can Eliminate & Prevent Solder Paste Dispensing Clog.

Before

Before

After

After

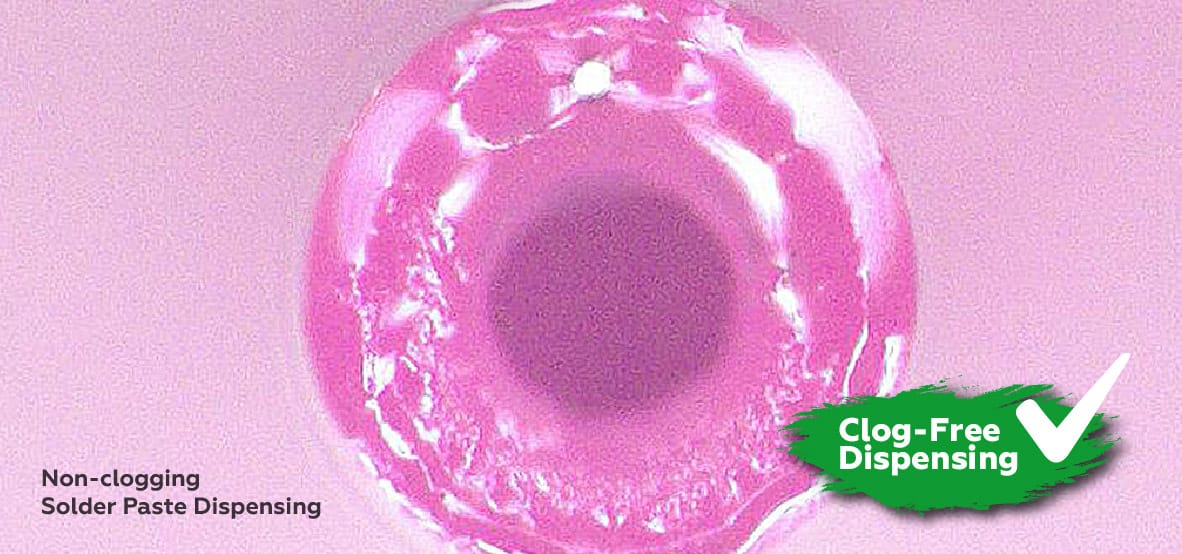

With the proper dispensing techniques, you can improve your process control and, in the end, saves costs and increases productivity. Clogged dispensing valves are indeed a headache when you do not carefully evaluate the process parameters, application, and limitations of the dispensing process.

As industry experts, NSW focuses on smart productivity and automated intelligent micro-dispensers. We aim to help operators increase productivity. We hope that our best practice guidelines can help you optimize processes and avert future liquid dispensing congestion issues.

Prevention of solder paste dispensing clogging can be indeed challenging. NSW dispensing equipment are innovatively built to give you clog-free dispensing optimization so that you won’t have to go through all these minute clogging headaches.

In the next article, find out the difference between contact dispensing vs fluid jetting. For more information, visit us on Linkedin and Facebook.

[Fancy_Facebook_Comments]