i-DR A300 Series

A301, A302, A304

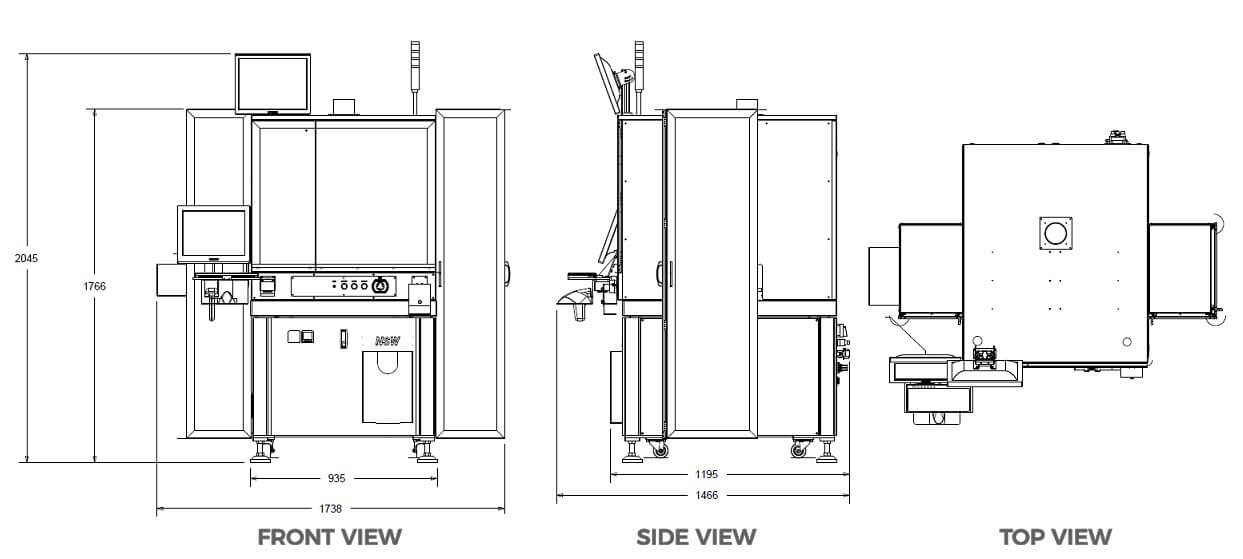

The NSW i-DR A300 Series, which includes models A301, A302, and A304 — also known as Automated Intelligent Fluid Dispensing Handler Systems — are designed for large-scale production, offering unparalleled precision in fluid dispensing. Built on a granite base for stability, these systems integrate advanced technologies for efficient, repeatable performance in mass production settings.

i-DR A301 – Single Pump System

Behold the revolutionized Single Pump System, The i-DR A301 excels in processing diverse automatic pipette types of large-scale protected semiconductor device packaging that requires extremely sensitive precision demands like 5G optical device, MEMS, SMD soldering, SMD components, and micro soldering. It is built with a fully enclosed cover on top of a solid reinforced granite base and gantry for maximum stability. Light, agile, and flexible, nozzles are easily changeable to fit the desired output. Its closed-loop linear encoding system syncs perfectly together with the machine’s primary XY gantry system. It allows an environment of extremely stable operations and higher precision outputs.

i-DR A302 – Dual Pump, Singular Excellence

The hot-selling i-DR A302 is a dual fluid dispensing pump system for those who demand higher quality results and advanced rapid production throughputs. It stands between the precision of the A301 and the blazing speeds of A304. It has a high capability to handle mid-to-high complex dispensing forms, MEMs, and memory chip products swiftly. In achieving optimum productivity, this microplate dispenser is equipped with the most advanced fluid equipment dual-pump system that runs simultaneously. This system is easy to use and dynamically programmable via its dual 3-axis fully motorized robot on top of its solid production board.

i-DR A304 – High Productivity Quad Pump System

The i-DR A304 revolutionizes production with its quad-pump technology, enabling precise, simultaneous dispensing of complex z-axis designs, enhancing efficiency and versatility. Its advanced multi-axis programmability accelerates dispensing, boosts throughput, and shortens cycle times. This system reduces material waste, ensures consistent quality, and cuts operational costs, addressing crucial manufacturing challenges with unmatched precision and efficiency.

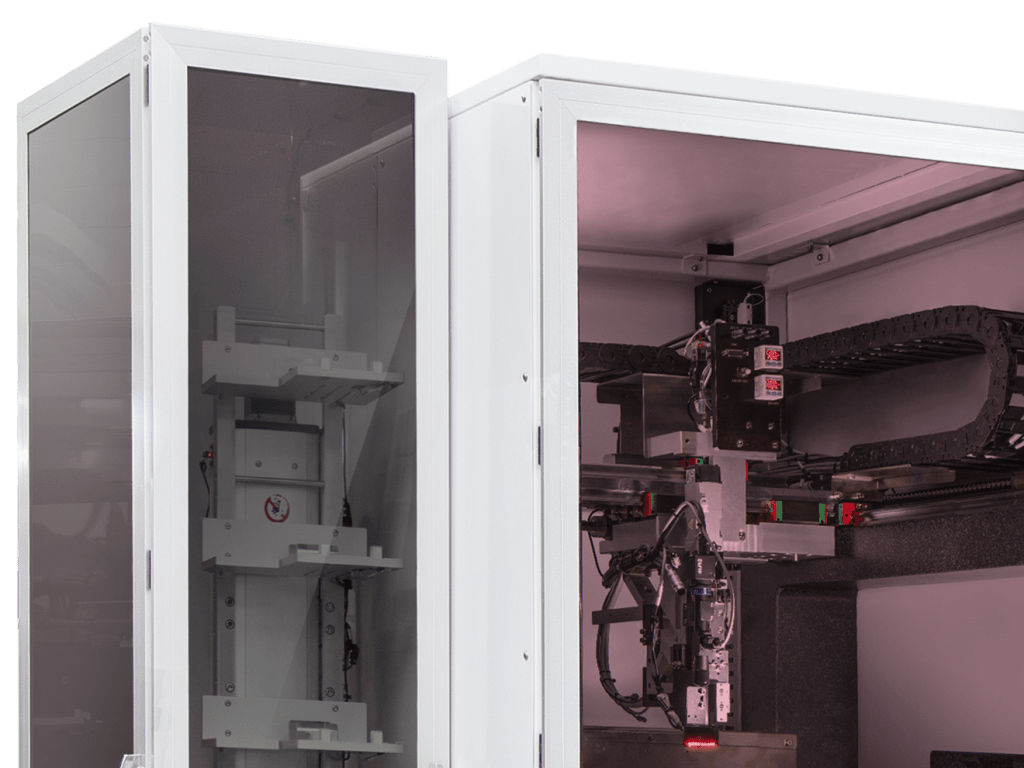

Smart Auto Magazine Handler

The A300 Series comes with sensors to detect subject to dispense. This feature enables a magazine holder to load and unload any dispensing subjects onto the workpiece automatically. After completion, you can extract the product by removing the entire magazine. On top of that, the sensors of the automated liquid dispenser will detect possible failures or misplacements caused by human or operation error as it automatically alerts the operator before system failure. It dramatically reduces downtime and prevents unnecessary chaos.

Industry 4.0: Revolutionizing Precision Dispensing

Step into Industry 4.0 with the NSW i-DR A300 Series, where precision dispensing meets intelligent automation. These advanced fluid dispensers are equipped with smart sensors, sophisticated algorithms, and machine-learning capabilities. It meticulously fine-tunes operational processes in real-time to ensure flawless execution in high-volume mass production settings.

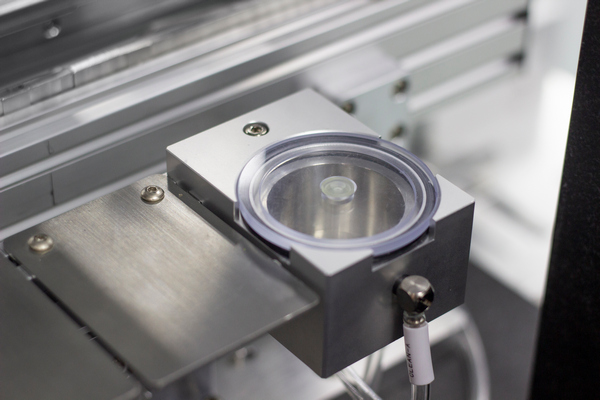

Smart Volume Control & Self-Weight Calibration

NSW innovative self-weighing calibration system uses an advanced cutting-edge algorithm to measure dispensing processes for volume and weight preciseness. Our Smart Volume Control automatically self-tunes to meet the desired dispense volume in light speed repeatedly. It eliminates any inconsistency and temperature instability during material dispensation that causes imprecisions or rejections.

Inline Dispensing Volume Monitoring

This technology allows the workpiece to be inspected by another inline equipment for flaws and imprecision. It notifies you by smartly indicating the location of the defect then automatically marks rejected workpieces on the server’s database. This feature saves cost and prevents future flaws and errors.

High Precision & Reduced Disparity

NSW dispensing handler is integrated with solid construction grade granite base, gantry and steel structures, inline dispensing volume monitoring compensation technology, and intelligent self-weight calibration features. It enables our dispensing equipment to achieve precision and sharp accuracy with variations that are a hundred times smaller than a human hair.

e-Mapping Function

NSW dispensing handler comes with an advanced e-mapping function. It enables you to use the e-map file as a guideline and path for the equipment to administer on a workpiece. Alternatively, you can use NSW’s integrated line scan camera feature to identify the dispensing area and XYZ position of the workpiece.

Granite Base Structure

& with Precision Craftsmanship

The system built is fully enclosed with a cover onto a solid granite base and gantry, which is a popular type of felsic intrusive igneous rock that is granular and phaneritic in texture. Because of its stable and goliath features, it is used mainly in the construction industry. This material is forced between other layers of rock by the natural pressure under the Earth’s surface. As a result, when compared to steel structures, granite delivers better performance in terms of stability, accuracy, and speed.

Vision Calibration System

Integrated with the advanced vision system to assist NSW pump heads, it quickly acquires the exact XY position of the dispensing location on a workpiece. This system enables you to achieve precise constant accuracy and eliminates system tolerances. The system can detect misaligned workpieces when a new workpiece is loaded into the system during a repeating dispensing process.

Lasered Height Examinations

Utilizing advanced laser beams enables the NSW dispensing handler to measure the surface height of the workpiece before any dispensing process begins. This non-contact measurement device helps you measure a variety of surfaces, including high-density holes, trenches, and cavity. It can determine surfaces like shiny metal to dark surfaces with extreme speed across all axis.

(Optional with confocal sensor systems)

Precision Tailored

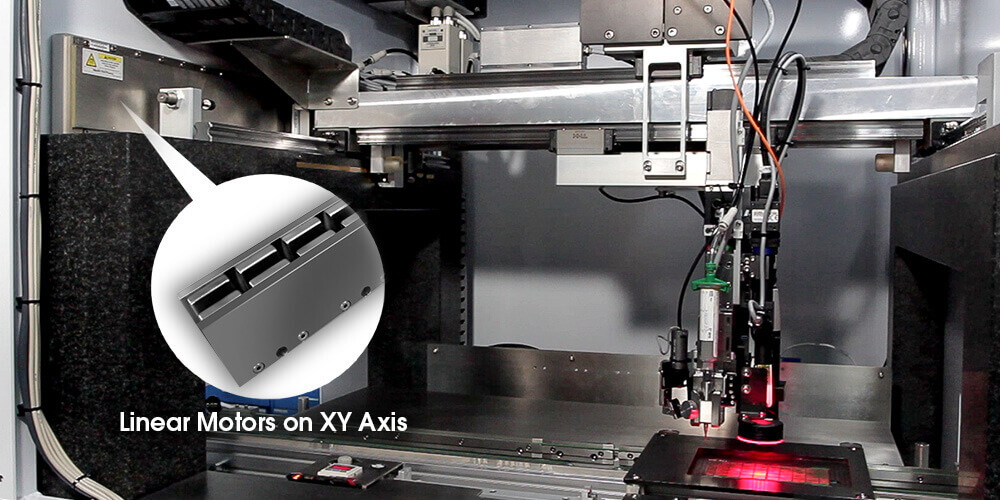

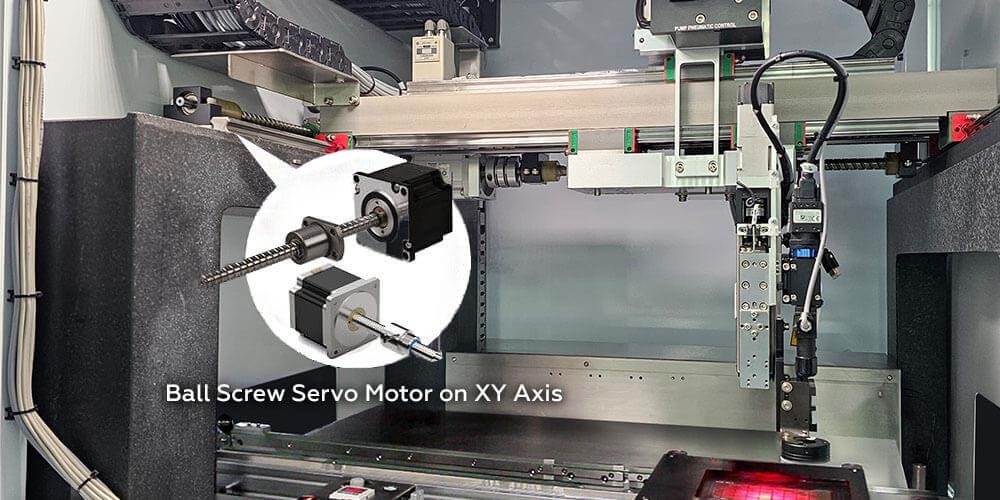

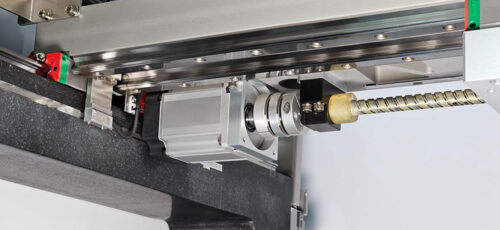

Linear VS Ball Screw Servo Motor

Maximize your production with the NSW i-DR A300 Series. Select the Linear Motor for peak speed and precision, or choose the Ball Screw Motor for a balance of quality and economy. Tailor your precision dispensing demands to fit your exact manufacturing needs.

Drag Here

Drag Here

Linear Motor: Unmatched Speed and Precision

Looking for production demands are centered around swift and exact movements? the Linear Motor configuration in the NSW i-DR A300 Series is ideal choice. It offers a seamless blend of high-speed operation and meticulous accuracy, making it ideal for dynamic manufacturing environments that require both rapid and precise actions.

Supported Models: i-DR A301L, & i-DR A302L

Ball Screw Motor: Cost-Effective Reliability

For manufacturing setups that prioritize economical solutions without compromising on performance, the Ball Screw Motor is an excellent choice. This configuration provides a reliable and precise operation, ensuring quality results while also catering to budget-conscious decisions in the NSW i-DR A300 Series.

Supported Models: i-DR A301, I-DR A302 & i-DR A304

More Features & Characteristics

Technical Specifications

| Features | i-DR A301 | i-DR A302 | i-DR A304 |

|---|---|---|---|

| Operating System | Windows 10 | Windows 10 | Windows 10 |

| NSW Dispensing Software | N Disp 3 WIN | N Disp 3 WIN | N Disp 3 WIN |

| Fluid Delivery System | SynchroPULSE-MICRO/LITE, PistonPRO 4+, HeliMASTER-3, DST Jetting, Piezoelectric Jetting, Time Pressure Dispenser | PistonPRO 4+, HeliMASTER-3, Piezoelectric Jetting | PistonPRO 4+ |

| Smallest Dispensing Size | ≥150µm | ≥150µm | ≥150µm |

| Motion Mechanism | 3 Axis, 1 Head | H-Type Gantry, 6 Axis, 2 Heads (Simultaneously/Independently) | 12 Axis, 4 Heads (Simultaneously / Independently) |

| Maximum Board Size (Length x Width) | L300mm x W210mm | L300mm x W210mm | L300mm x W210mm |

| Motion Gantry System (XY Axis) | Iron Core Linear Motor Drive / Precision Rolled Ball Screw with Servo Motor Drive | Iron Core Linear Motor Drive / Precision Rolled Ball Screw with Servo Motor Drive | Precision Rolled Ball Screw with Servo Motor Drive |

| Iron Core Linear Motor Drive Support (XY Axis) | Yes | Yes | - |

| Primary XY Axis Linear Encoder | 0.5µm/Step Linear Type | 0.5µm/Step Linear Type | 0.5µm/Step Linear Type |

| Primary XY Axis Resolution | 0.5µm | 0.5µm | 2µm |

| Primary Head XY Axis Accuracy (within Dispensing Area) | ±15µm/200mm/23°C | ±15µm/200mm/23°C | ±15µm/200mm/23°C |

| Secondary Head XY Axis Accuracy (within Dispensing Area) | - | ±20µm/200mm/23°C | ±20µm/200mm/23°C |

| Primary Head XY Axis Repeatability (within Dispensing Area) | ±5µm | ±5µm | ±5µm |

| Secondary Head XY Axis Repeatability (within Dispensing Area) | N/A | ±20µm | ±20µm |

| Z Axis Actuator | Servo Motor Drive with Linear Encoder | Servo Motor Drive with Linear Encoder | Servo Motor Drive with Linear Encoder |

| Z Axis Resolution | 0.6µm | 0.6µm | 0.6µm |

| Z Axis Accuracy | ±10um/50mm / 23°C | ±10um/50mm / 23°C | ±10um/50mm / 23°C |

| Z Axis Repeatability | ±5µm | ±5µm | ±5µm |

| Height Scanning Sensor's Linearity** | 25µm Laser Sensor **Option w/ Confocal | 25µm Laser Sensor **Option w/ Confocal | 25µm Laser Sensor **Option w/ Confocal |

| Bi-directional Material Stabilizer | Ready (SynchroPULSE-MICRO) | - | - |

| Weighing Scale Resolution | 0.01mg *Optional | 0.01mg *Optional | 0.01mg *Optional |

| SECS/GEM Support | *Optional | *Optional | *Optional |

**Optional: 2.5pm Confocal Chromatic Sensor. *Tailored customization and optional features are available, with associated considerations for costing.

*All specification results shown may vary depending on test method. All products, specifications and data are subject to change without notice to improve reliability, function or design or otherwise.