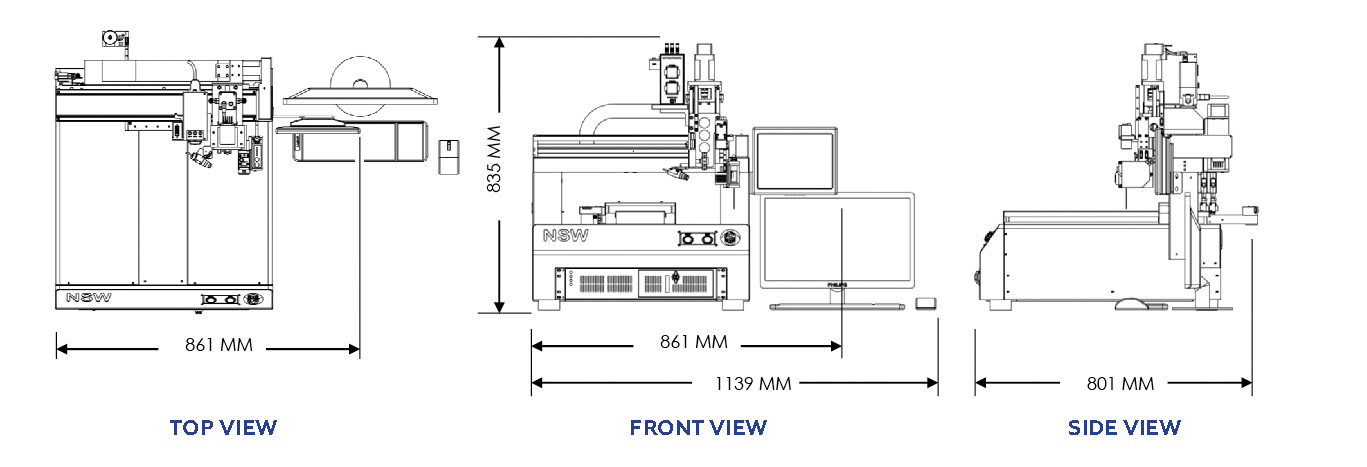

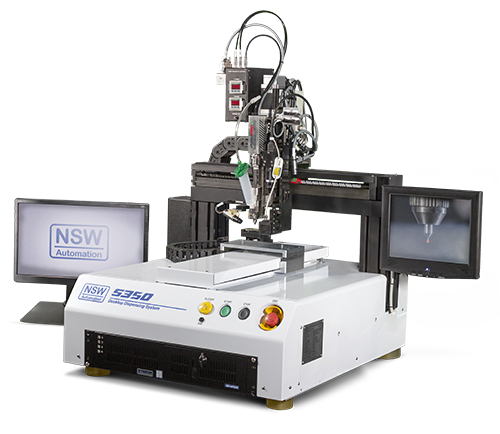

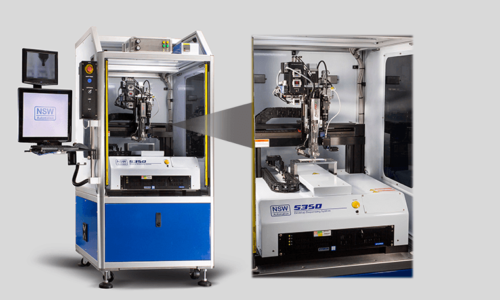

i-DR S350 | Desktop Dispenser

The i-DR S350 is an easy set-up benchtop/desktop format precision fluid dispenser. Its compact size is designed for the highest flexibility, this allows engineers to relocate without consideration of space limitations conveniently.

R&D Support

Features

High

Precision

High

Flexibility

(Pump conversion)

Tiny Fluid Dispensing System

But Power Packed Features

The i-DR S350 is cost-efficient, mobile and, suitable for R&D departments or small scale manufacturers. It is highly flexible and just as powerful as other advanced NSW fluid dispensing systems. It comes with 3D dispensing, pre-dispense simulation, vision mapping, and calibration functions. This extreme fluid dispensing application has excellent positioning capabilities via its closed-loop servo driven system combined with precision ground balls screws transmission mechanisms. Compared with other liquid drawing systems, this liquid dispenser is suitable to handle high mix/low volume production, R&D prototype sample production, and repairing jobs in speedy setup and conversions.

Adaptive Pump Switching Technology

The i-DR S350 boasts a versatile pump exchange system, enabling seamless transitions between various pump types, including jet pumps, contact dispensing pumps, and other NSW pumps. This adaptability ensures that the dispenser meets a wide range of application demands with precision and efficiency. Whether for high-precision R&D projects or small-scale manufacturing, the i-DR S350’s ability to switch pumps at rapid speed makes it a highly flexible solution for diverse applications.

Optional Enclosure Ensures Workforce Safety

Besides productivity and ease of use, safety plays a paramount role in keeping our workforce safe. The i-DR S350 features an optional full-range failsafe CE enclosure version that is completely CE certified. It automatically shuts down upon the detection of foreign objects or movement that is within the enclosed workspace.

Delivering CE Certified Innovative Solutions

NSW provides technologically innovative, performance reliable, and distinctive encapsulation solutions to global users. Not only do we live up to our product standards and attain CE certification, but we have a team of professional and experienced R&D engineers. They are always researching and developing new fluid dispensing valve technology. With our capabilities and service results today, we can help you in resolving your specific dispensing challenges.

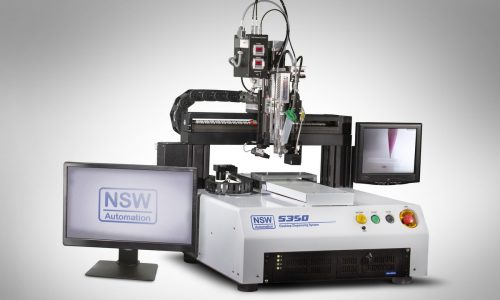

350mm x 350mm Large Dispensing Area

It has a large dispensing area that can work on workpieces of any shape or contour without any special jig required. Flexible with options to interchange NSW dispensing pump heads and valves increases adaptability to fit varying scenarios.

Vision Calibration System

Integrated with the advanced vision system to assist NSW pump heads, it quickly acquires the exact XY position of the dispensing location on a workpiece. This system enables you to achieve precise constant accuracy and eliminates system tolerances. The system can detect misaligned workpieces when a new workpiece is loaded into the system during a repeating dispensing process.

Lasered Height Examinations

Utilizing advanced laser beams enables the NSW dispensing handler to measure the surface height of the workpiece before any dispensing process begins. This non-contact measurement device helps you measure a variety of surfaces, including high-density holes, trenches, and cavity. It can determine surfaces like shiny metal to dark surfaces with extreme speed across all axis.

(Optional with confocal sensor systems)

More Features & Characteristics

R&D Support Features

This series is designed for a cleanroom environment. It has interchangeable pump heads, larger dispensing working space that enables engineers to work on larger wafers, device or workpieces. The system saves space, flexible, and convenient from utilizing any dispensing application dynamically.

Auto Nozzle Tip Cleaner

Equipped with an automatic nozzle tip cleaning feature, it can remove any impurities and unwanted existing materials after long operating hours. You can summon cleaning any time to ensure continual performance.

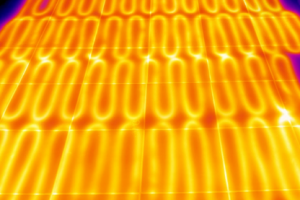

Smart Heater Control

Integrated with programmable workpiece heater to warm up any dispensing subject on board according to your recipe. Designed with industrial standard preciseness with its configurable temperature control capability NSW advanced heater system can maintain temperature consistently.