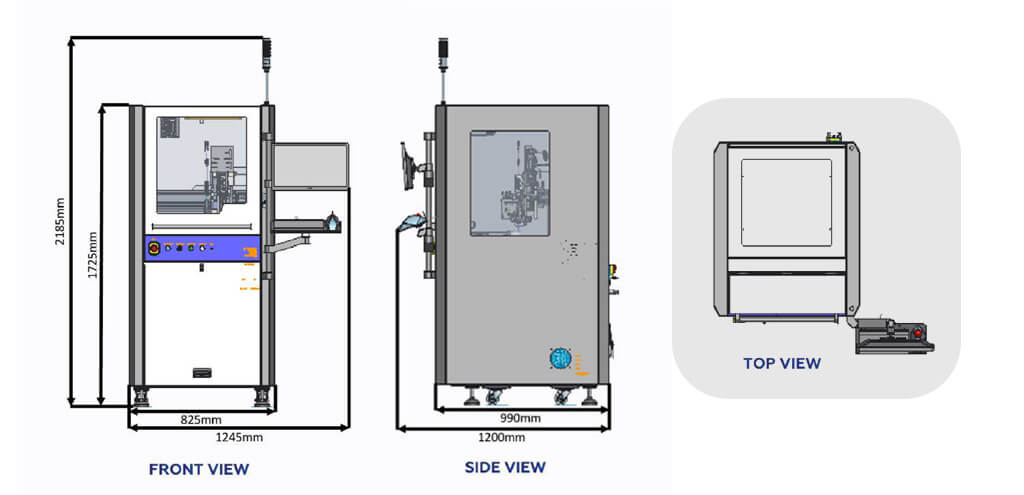

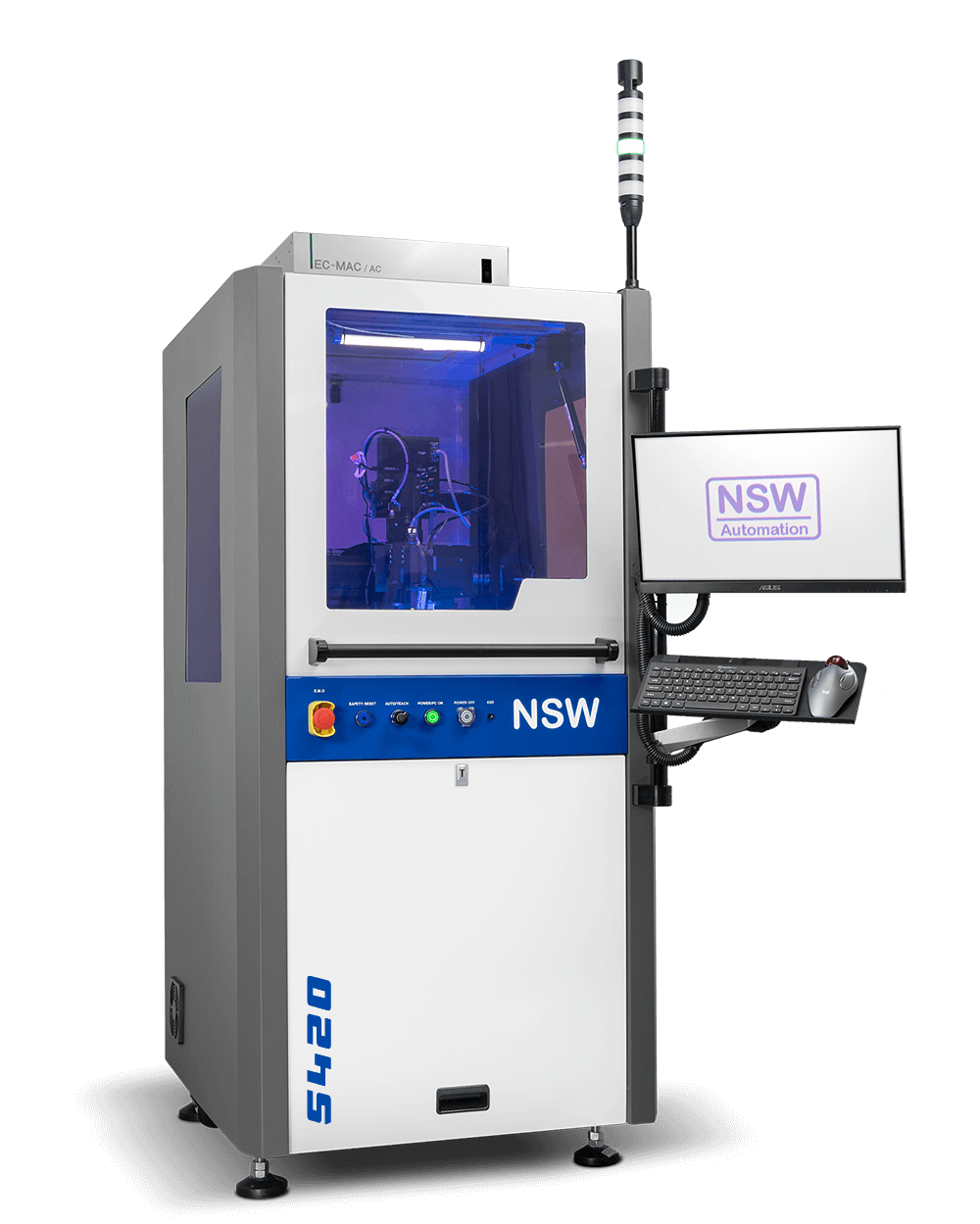

i-DR S420 Compact Smart Dispenser

The New i-DR S420 has undergone a remarkable makeover, introducing a cutting-edge dispensing system that offers a “One-for-all” solution. It’s a CE certified platform, ensuring both safety and ergonomic operation for users.

Extreme Accuracy

All-in-One Solution

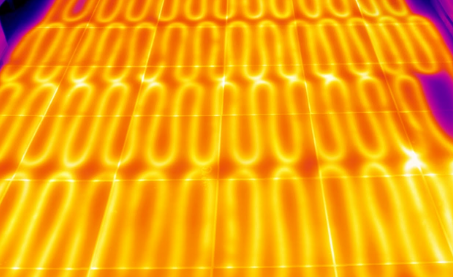

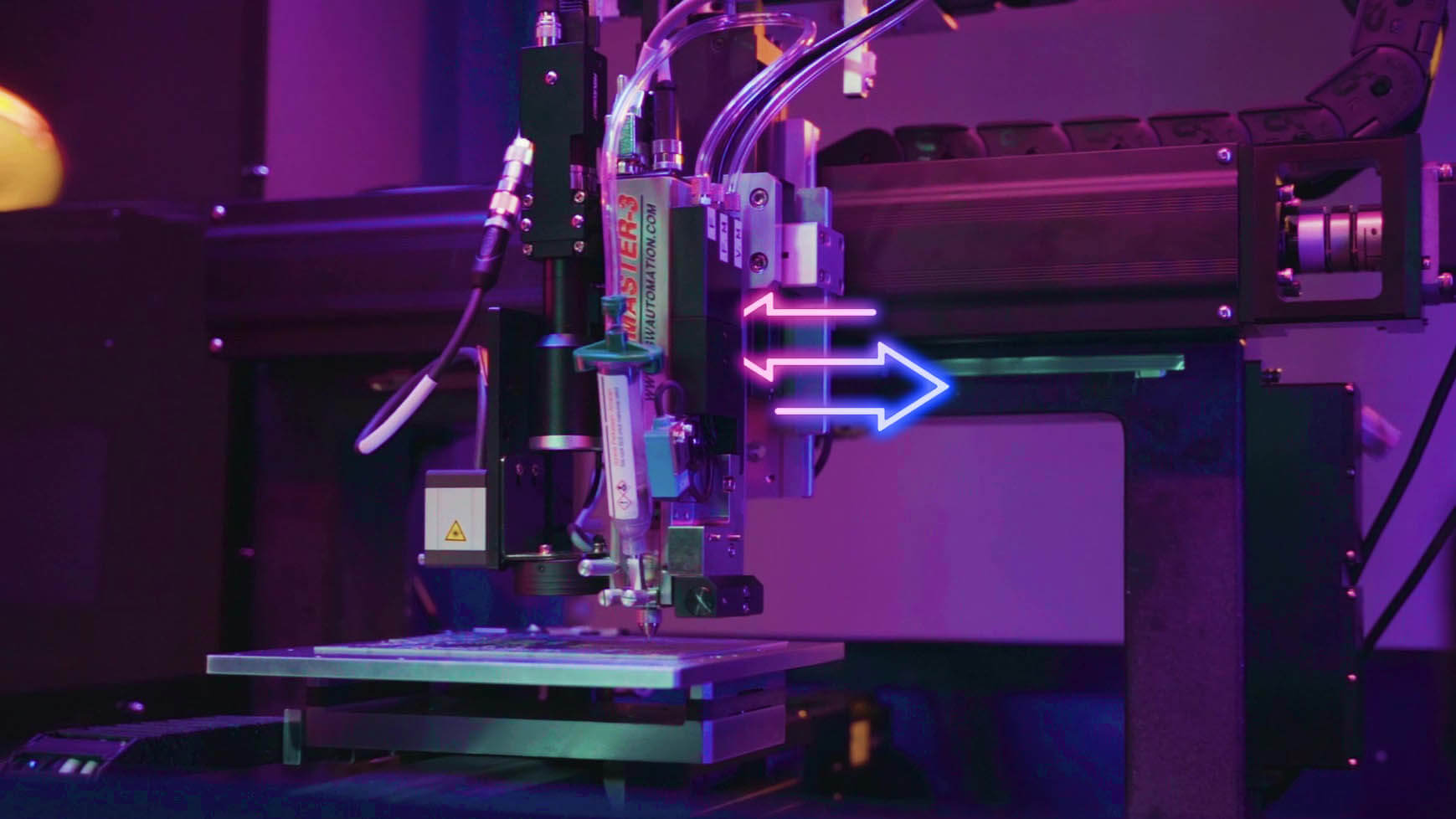

This system has significantly revamped to boost better dispensing performance and provide more robust operational advantages to optimize the user experience. It has been redesigned with all motors to be directly driven, resulting in better motion accuracy after long operation hours with the ability to switch pumps quickly.

The new S420 micro-dispenser is now armed with a new laser height sensing system and full enclosure featured with safety interlock function and HEPA filter to prevent dust from contaminating the dispenser’s workspace. Compatible with 5 types of different dispensing pump technologies to maximize the system competencies and usage: Squeezing micro-dispensing / Volumetric dispensing / Auger dispensing / Non-contact Jetting / Time pressure dispensing.

Product Features & Highlights

Fully Customizable

Tailored Dispensing Solutions

Experience the future of dispensing with our fully customized solutions. Our dispensers are designed to adapt to your unique requirements, providing tailored precision and convenience. Explore limitless possibilities with our cutting-edge technology.

Clean Workspaces with

Industrial HEPA Filter

The S420 micro-dispenser features a high-efficiency HEPA filter system, keeping your workspace clean and free from contaminants, ensuring precision and quality in your dispensing processes.

CE Certified Excellences

i-DR S420 Compact Smart dispenser proudly carries the CE certification, signifying its rigorous compliance with European Union standards. This mark of distinction ensures that our machine is not only of the highest quality but also meets the most stringent safety and regulatory requirements.

Granite Base Structure

& with Precision Craftsmanship

The system built is fully enclosed with a cover onto a solid granite base and gantry, which is a popular type of felsic intrusive igneous rock that is granular and phaneritic in texture. Because of its stable and goliath features, it is used mainly in the construction industry. This material is forced between other layers of rock by the natural pressure under the Earth’s surface. As a result, when compared to steel structures, granite delivers better performance in terms of stability, accuracy, and speed.

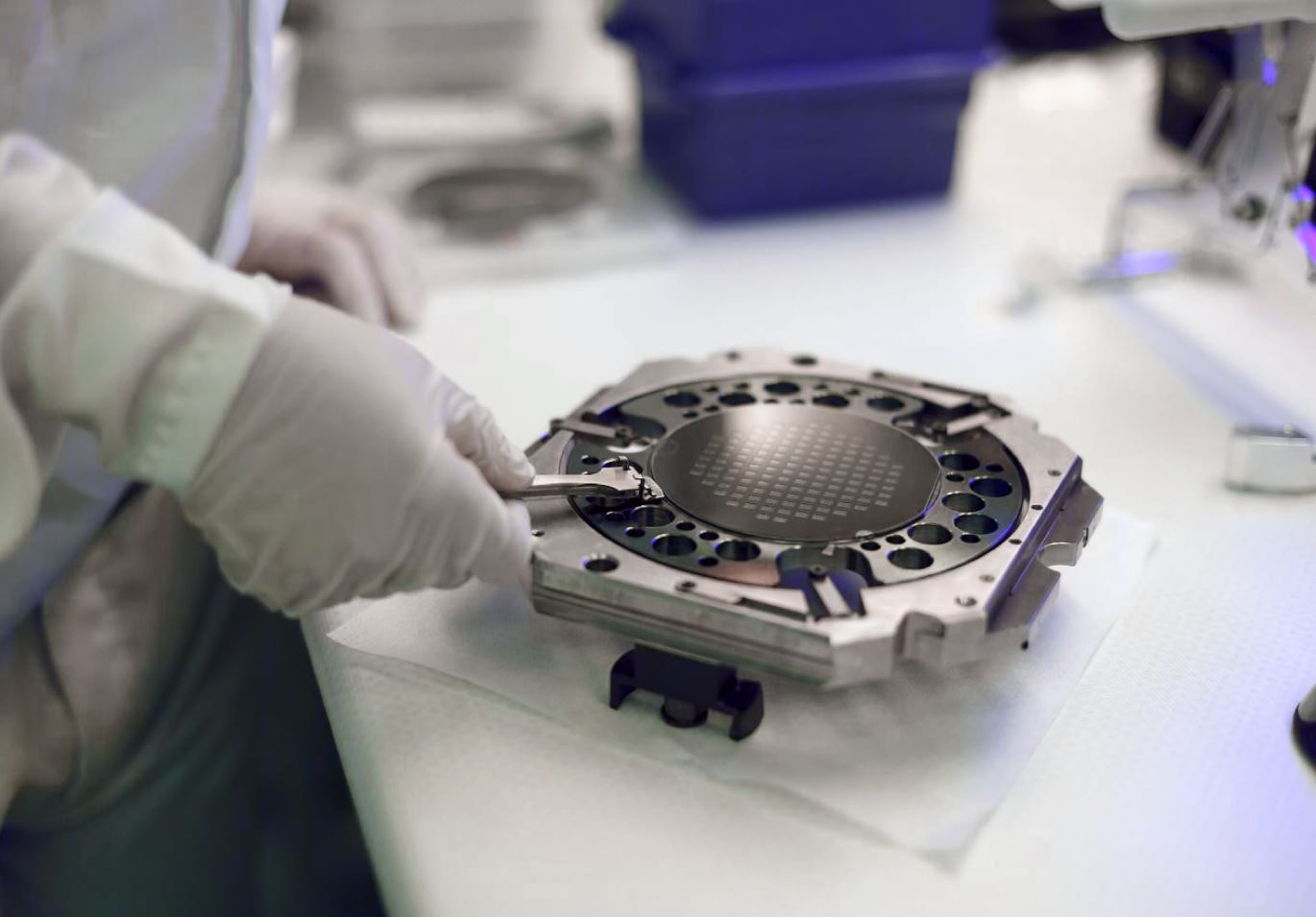

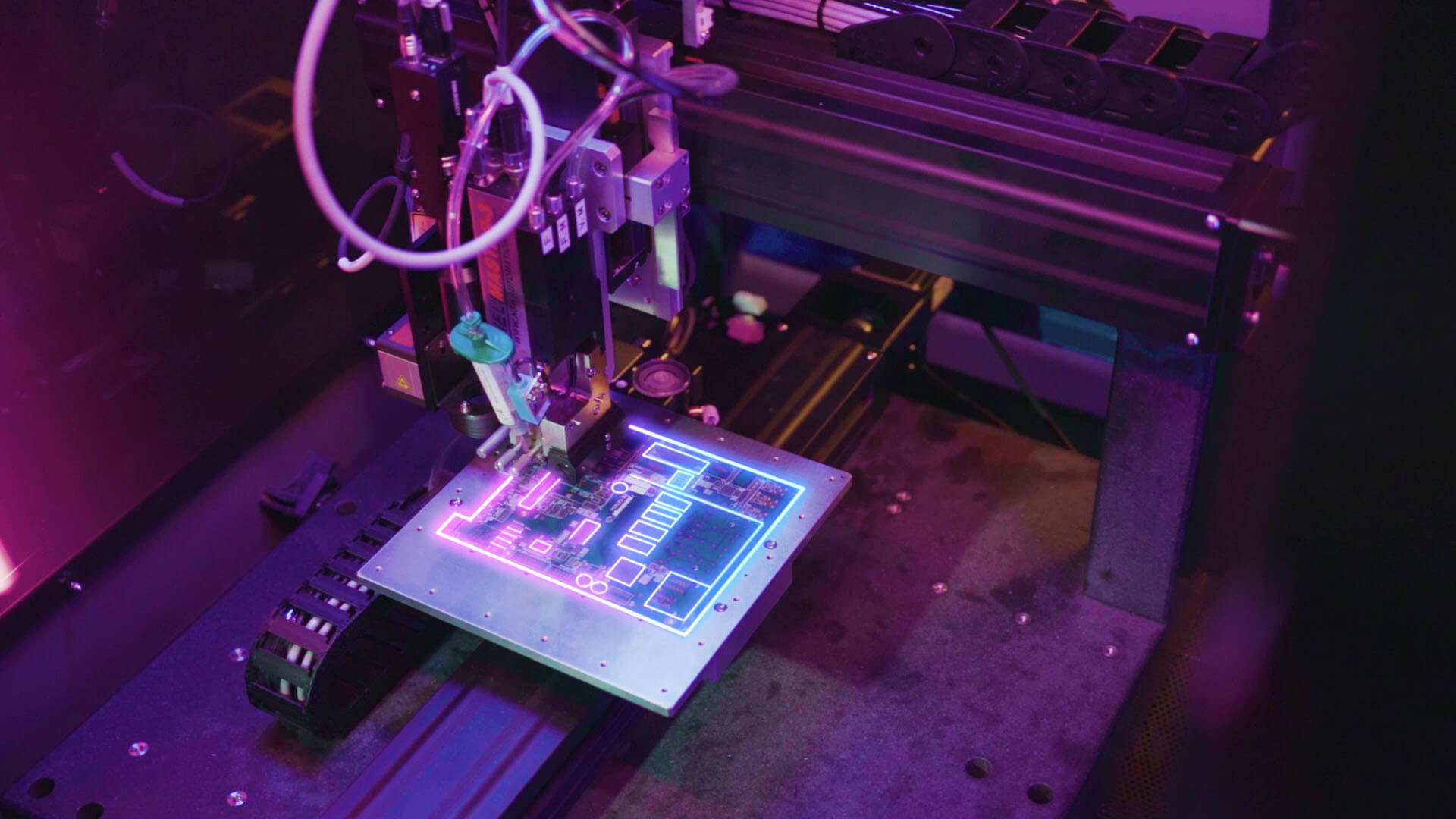

Vision Calibration System

Integrated with the advanced vision system to assist NSW pump heads, it quickly acquires the exact XY position of the dispensing location on a workpiece. This system enables you to achieve precise constant accuracy and eliminates system tolerances. The system can detect misaligned workpieces when a new workpiece is loaded into the system during a repeating dispensing process.

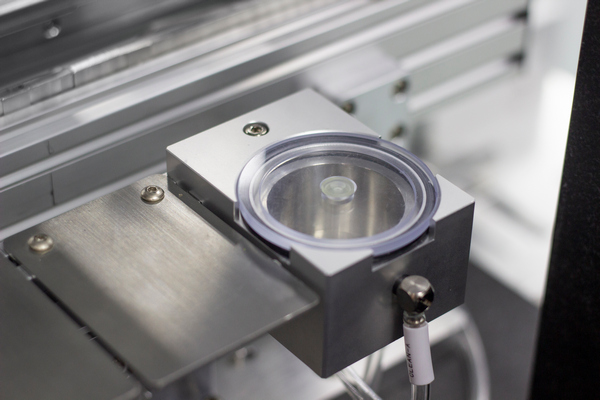

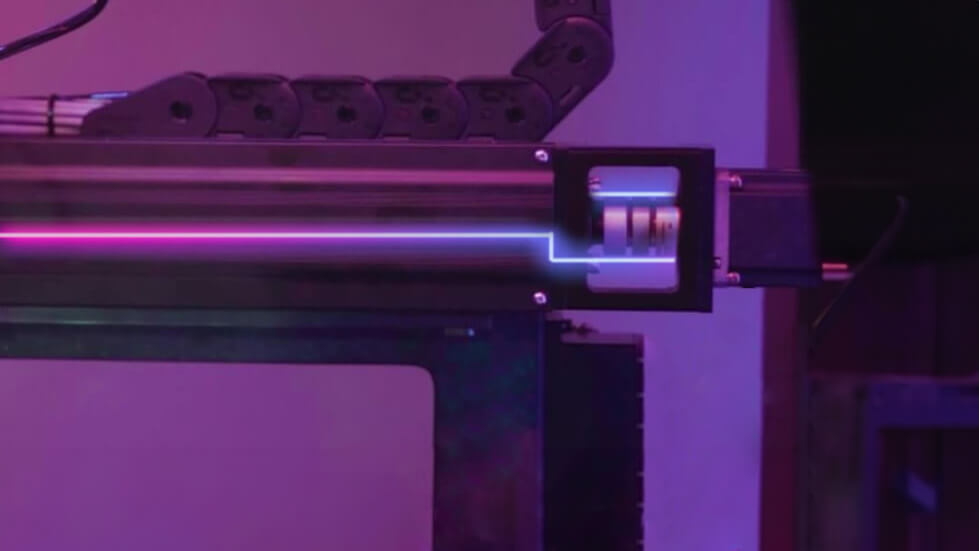

Lasered Height Examinations

Utilizing advanced laser beams enables the NSW dispensing handler to measure the surface height of the workpiece before any dispensing process begins. This non-contact measurement device helps you measure a variety of surfaces, including high-density holes, trenches, and cavity. It can determine surfaces like shiny metal to dark surfaces with extreme speed across all axis.

(Optional with confocal sensor systems)