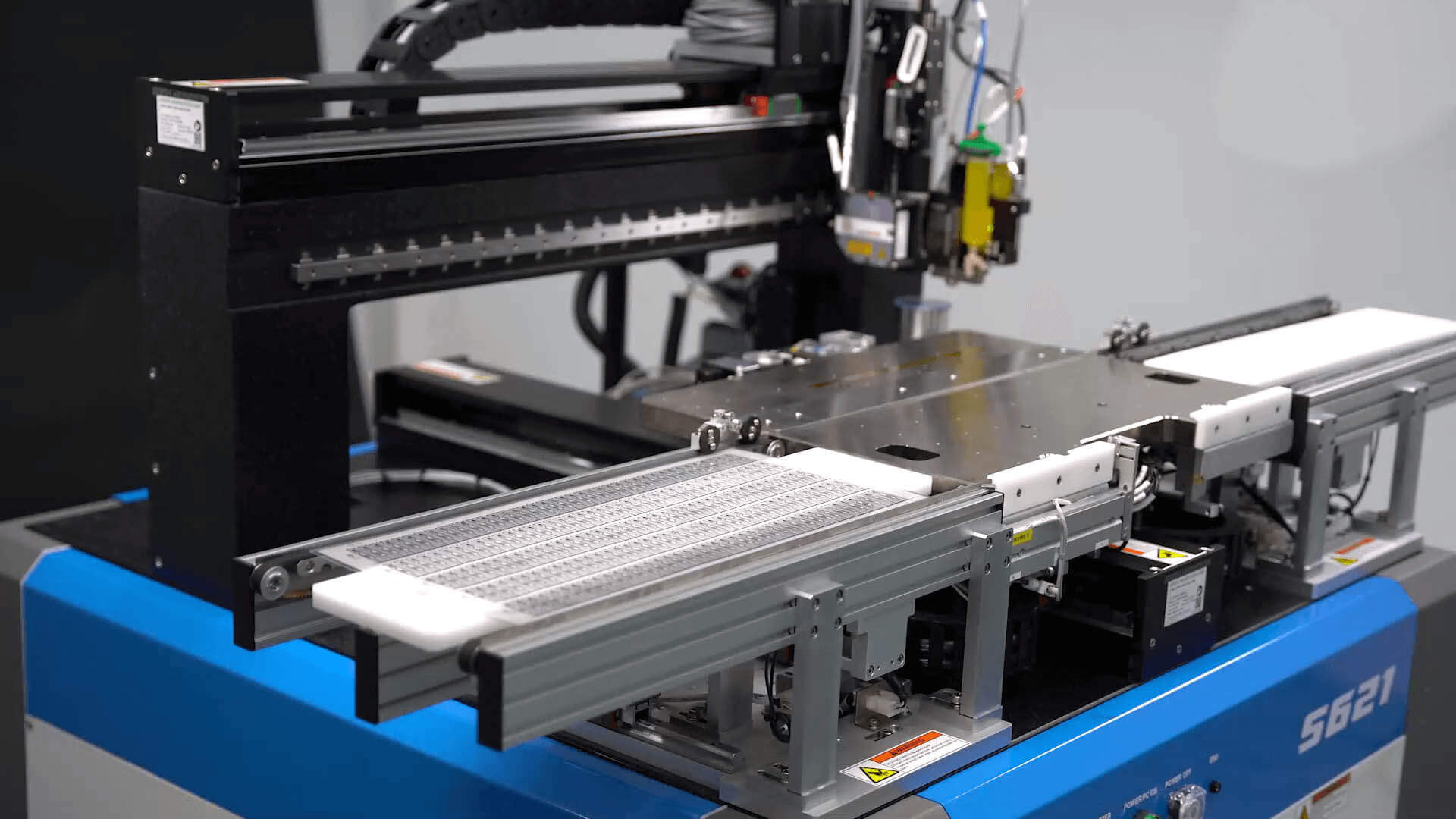

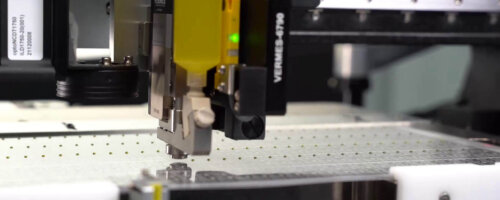

i-DR S621 Standalone Dispensing System

Breakthrough custom-built and designed for the unique demands of the biotech and medical industry.

Built & Optimized for

Biotech & Medical Industries

Optioned with inline conveyor operation function

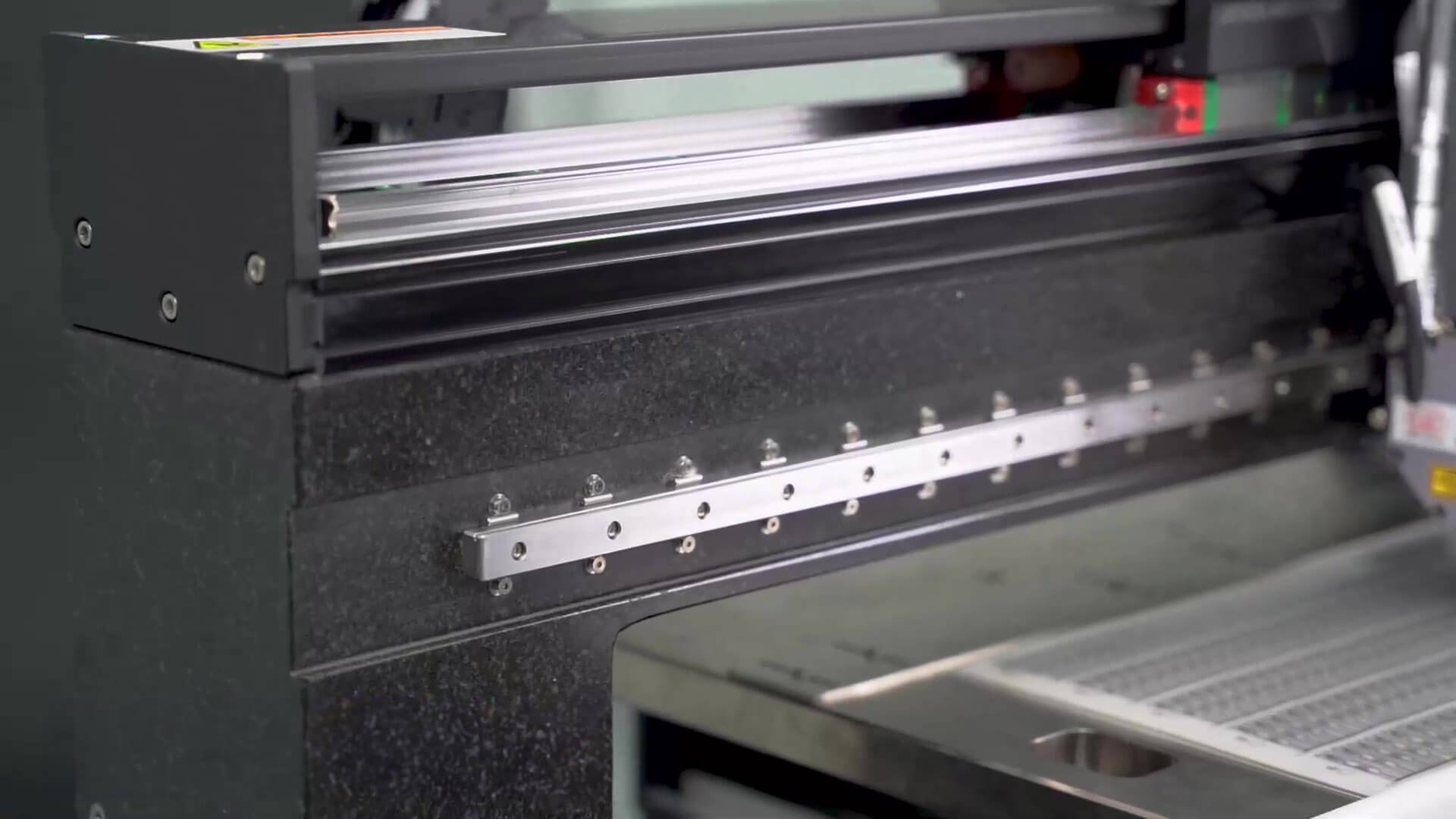

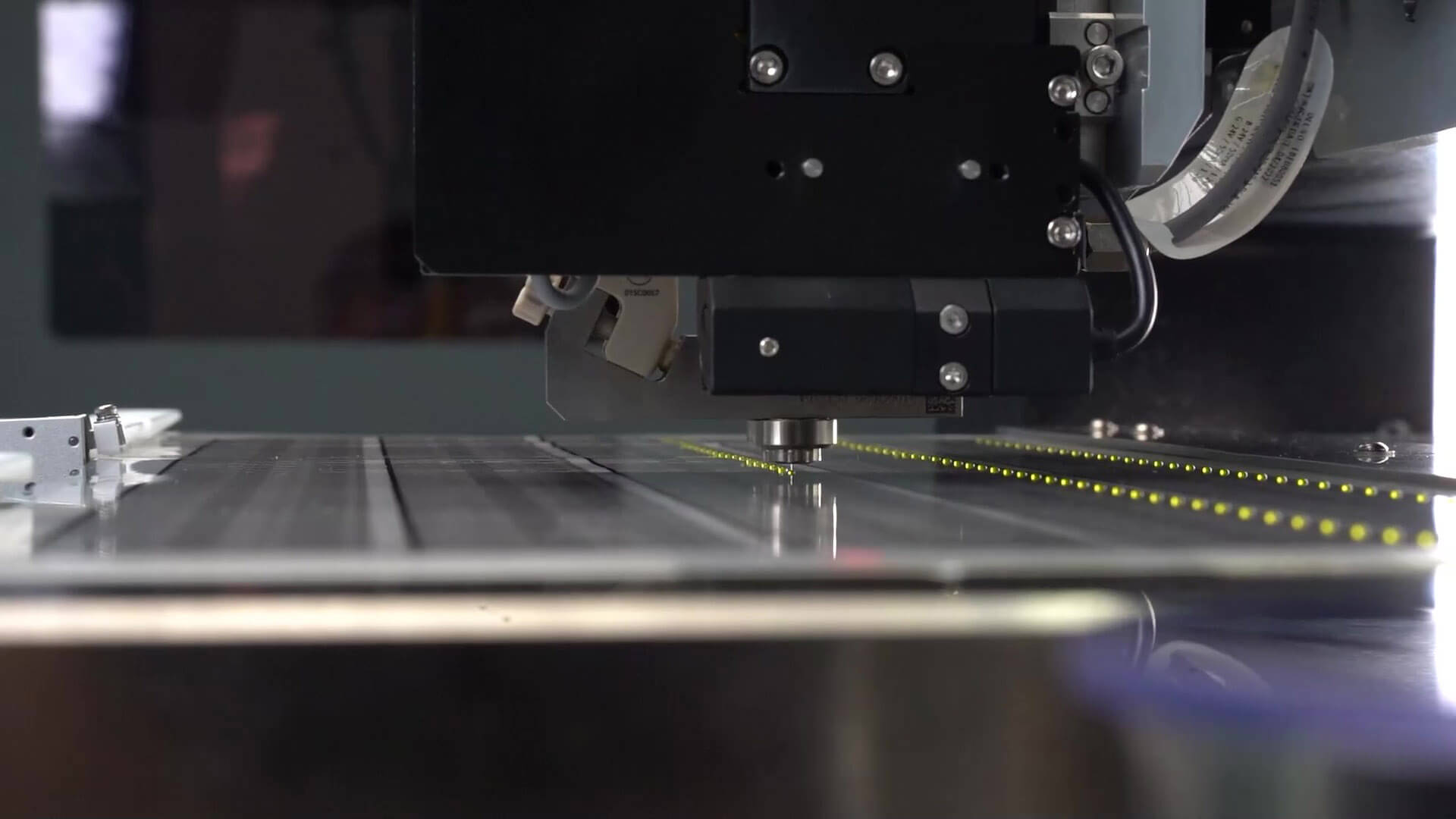

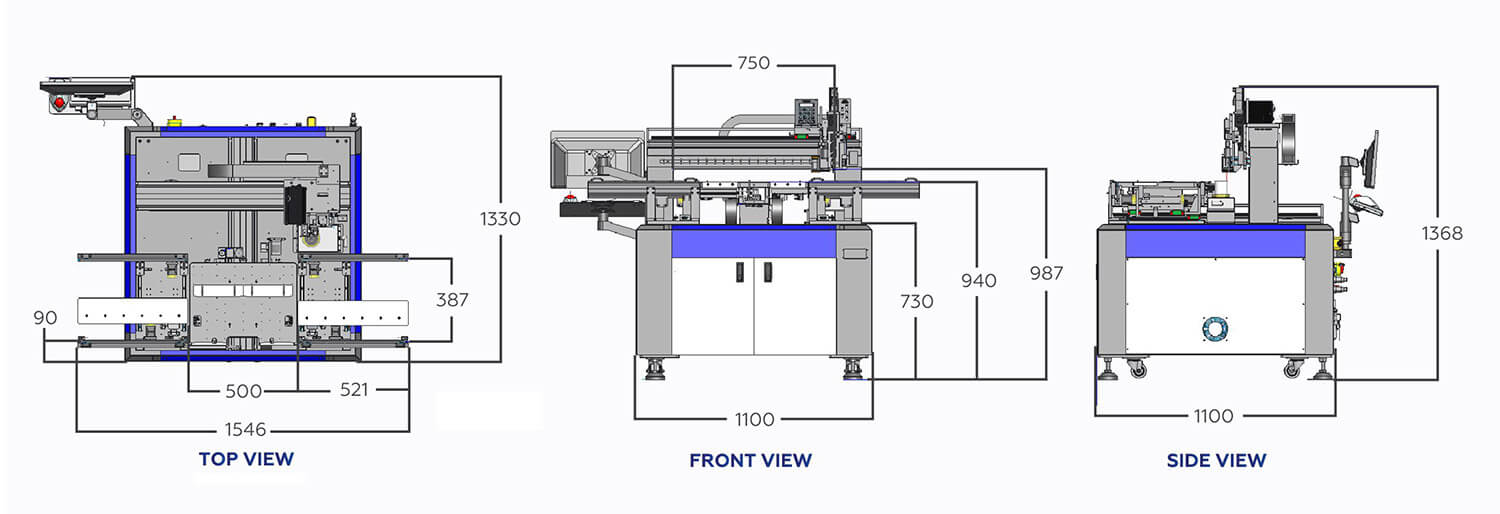

This precision micro-dispenser is not just advanced; it’s custom-built for the unique demands of the biotech industry, with a particular focus on biology test kits, bioscience production, and other similar applications. Its unparalleled precision and efficiency redefine the standards for tailored dispensing solutions. The NSW S621 incorporates cutting-edge technology, ensuring an extraordinary level of accuracy on a 600x600mm, extremely large dispensable area. Tailored to the stringent requirements of the industry’s sector, this dispenser is more than a machine; it’s a game-changer for biotech device manufacturing.

The NSW Dynamic Jet feature allows for uninterrupted and seamless high-speed dispensing, it efficiently jets multiple droplets in one swift motion without quality compromise. Embrace a new era in precision and efficiency with the NSW S621, where customization meets cutting-edge technology, setting a higher standard for today’s biotech manufacturing and reshaping the possibilities in the biotech industry.