W12-2020 Wafer Handling Dispenser

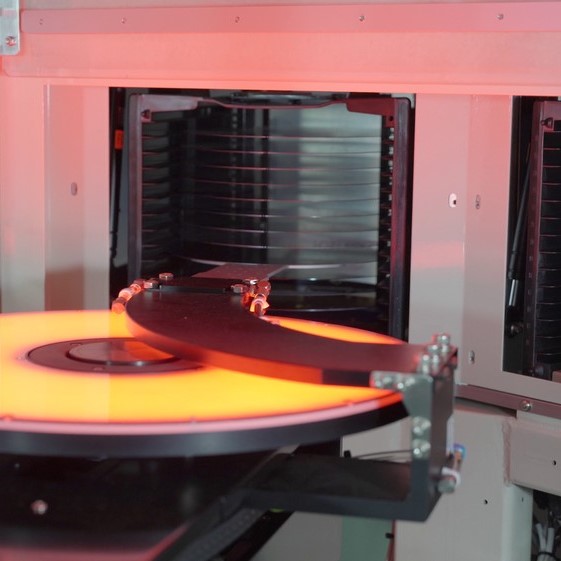

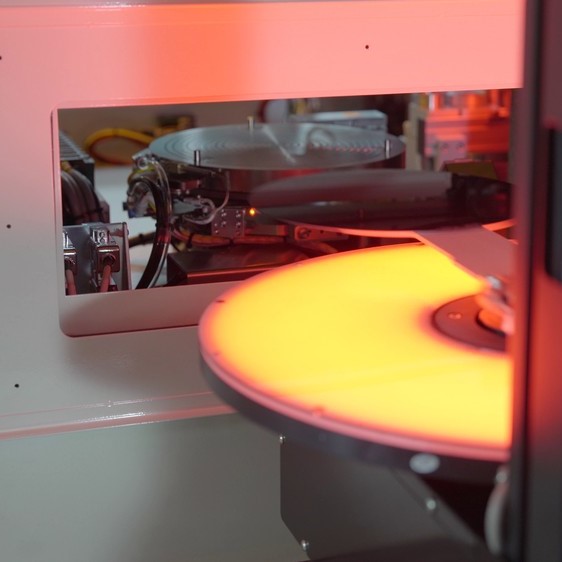

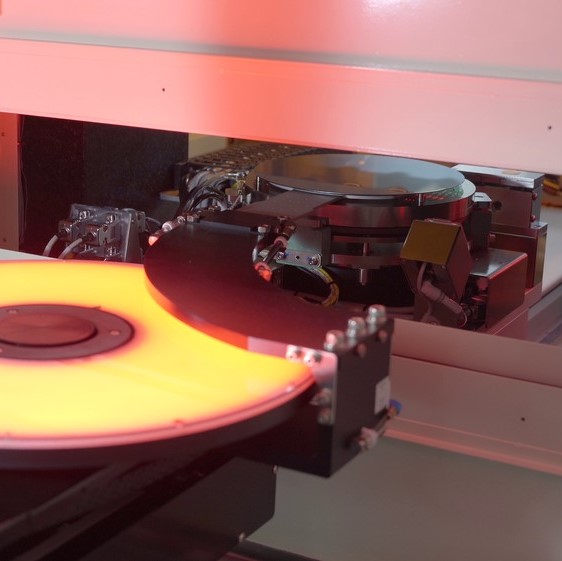

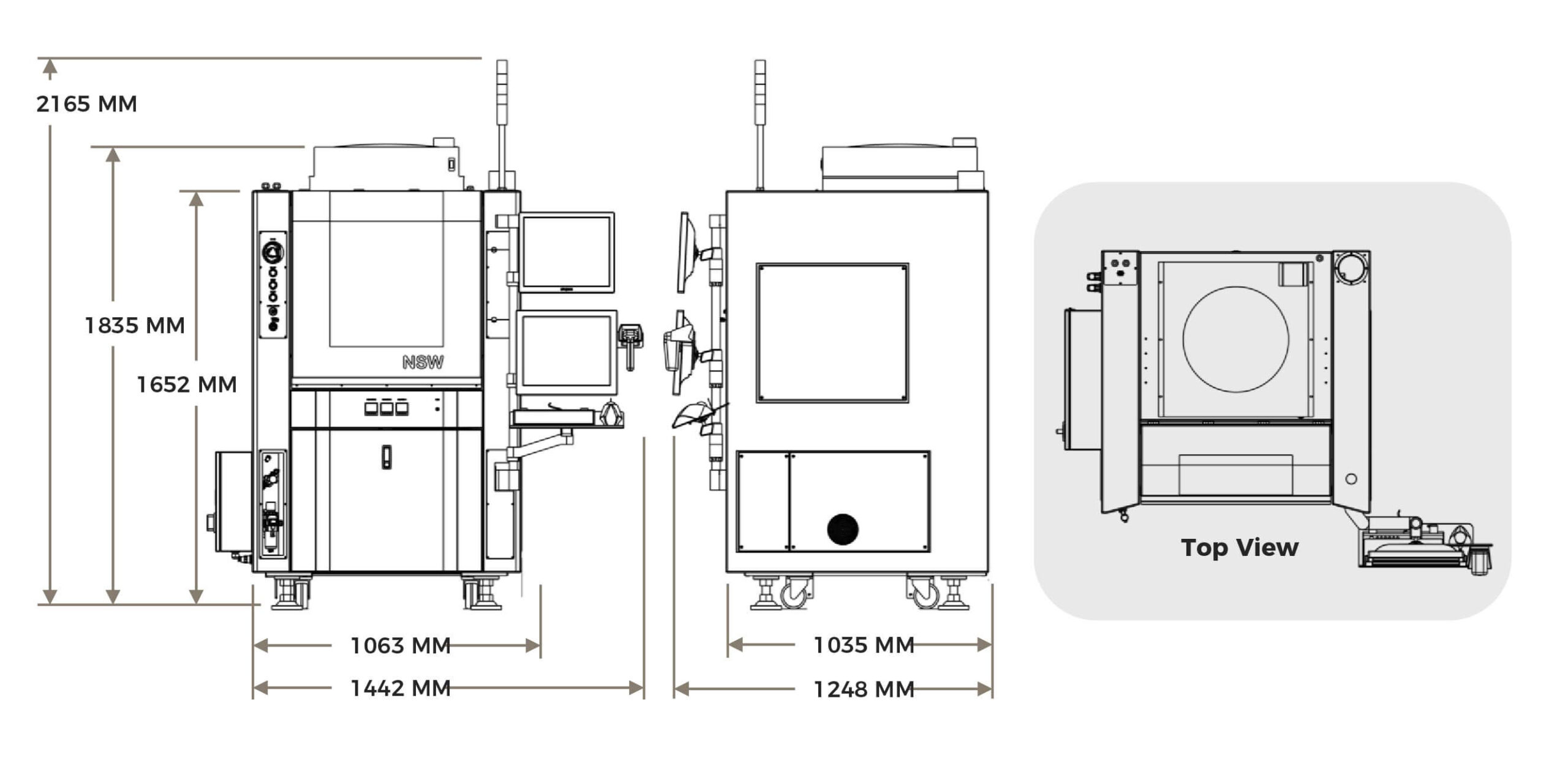

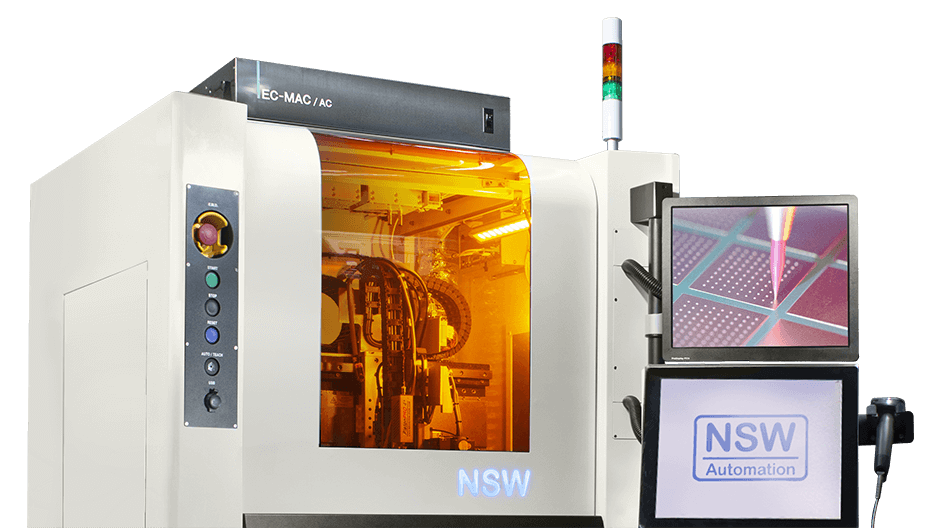

This precision mass production system for wafer-level dispensing supports processes such as underfill, micro-dispensing, and coating. Its main features include a granite platform, 12-inch wafer support, SMEMA compliance, full automation cell configurability, AMHS interface, temperature control, and compatibility with various dispensing systems.

Streamline & Elevate

Your Wafer Production

Elevate your wafer-level dispensing with W12-2020 – the cutting-edge solution for high-precision semiconductor production. Designed to meet the stringent requirements of the industry, armed with automatic wafer loading and unloading handling function that streamlines the dispensing process like never before.

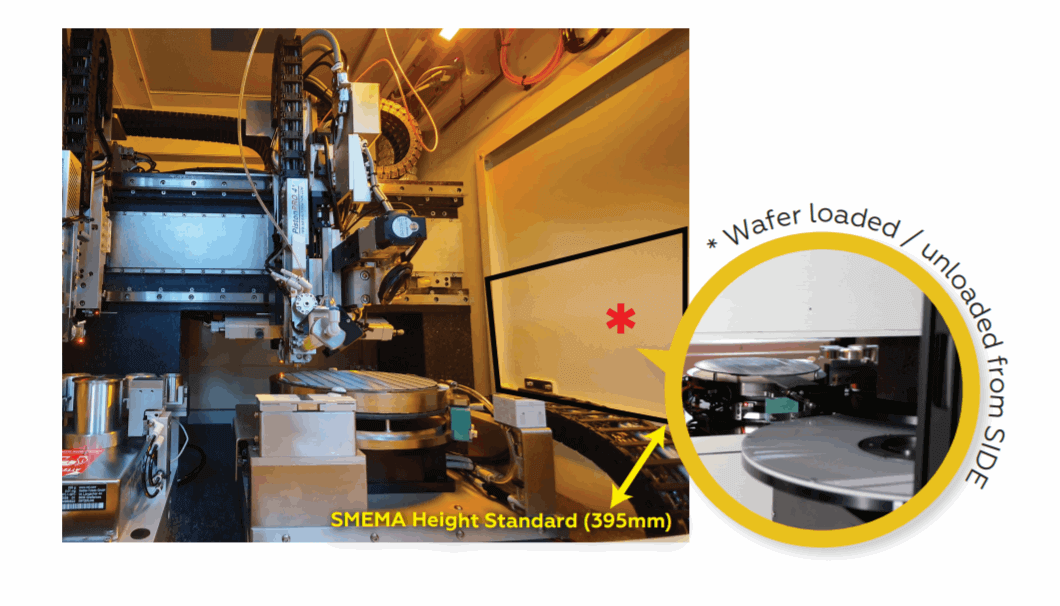

The equipment is fully customizable to your specific needs. Its granite platform is second to none, delivering unparalleled stability and precision. Comes with wafer map or CAD import function, large XY axis moving stroke of 600mm x 400mm, and a working envelope of at least 305mm x 305mm, this equipment can handle 12-inch wafers with ease, ensuring that every wafer dispensing process is carried out to meet the highest quality standards.

Product Highlights

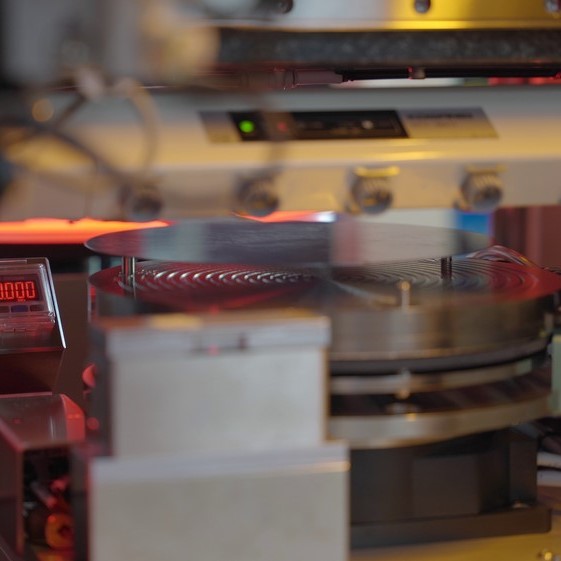

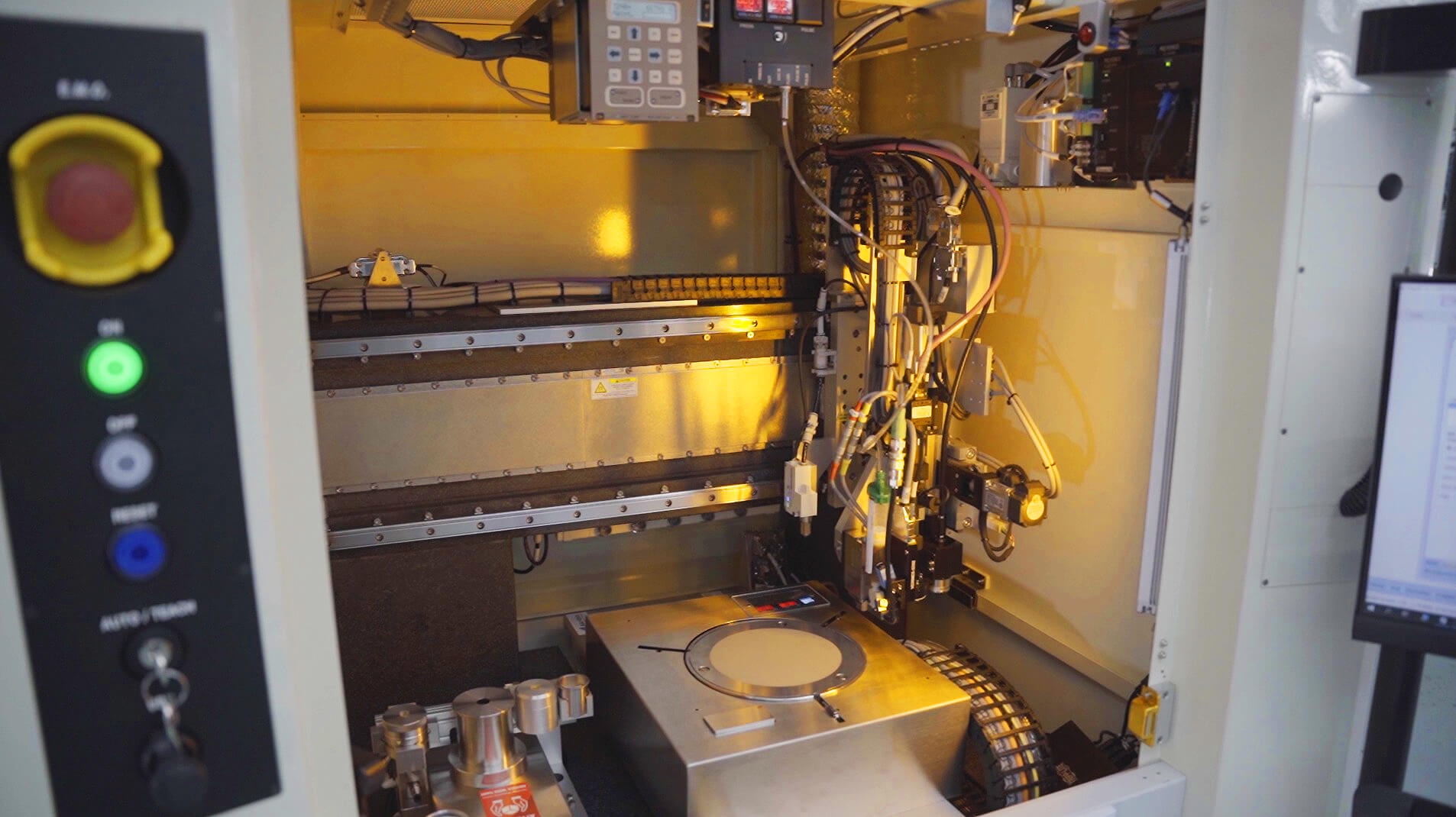

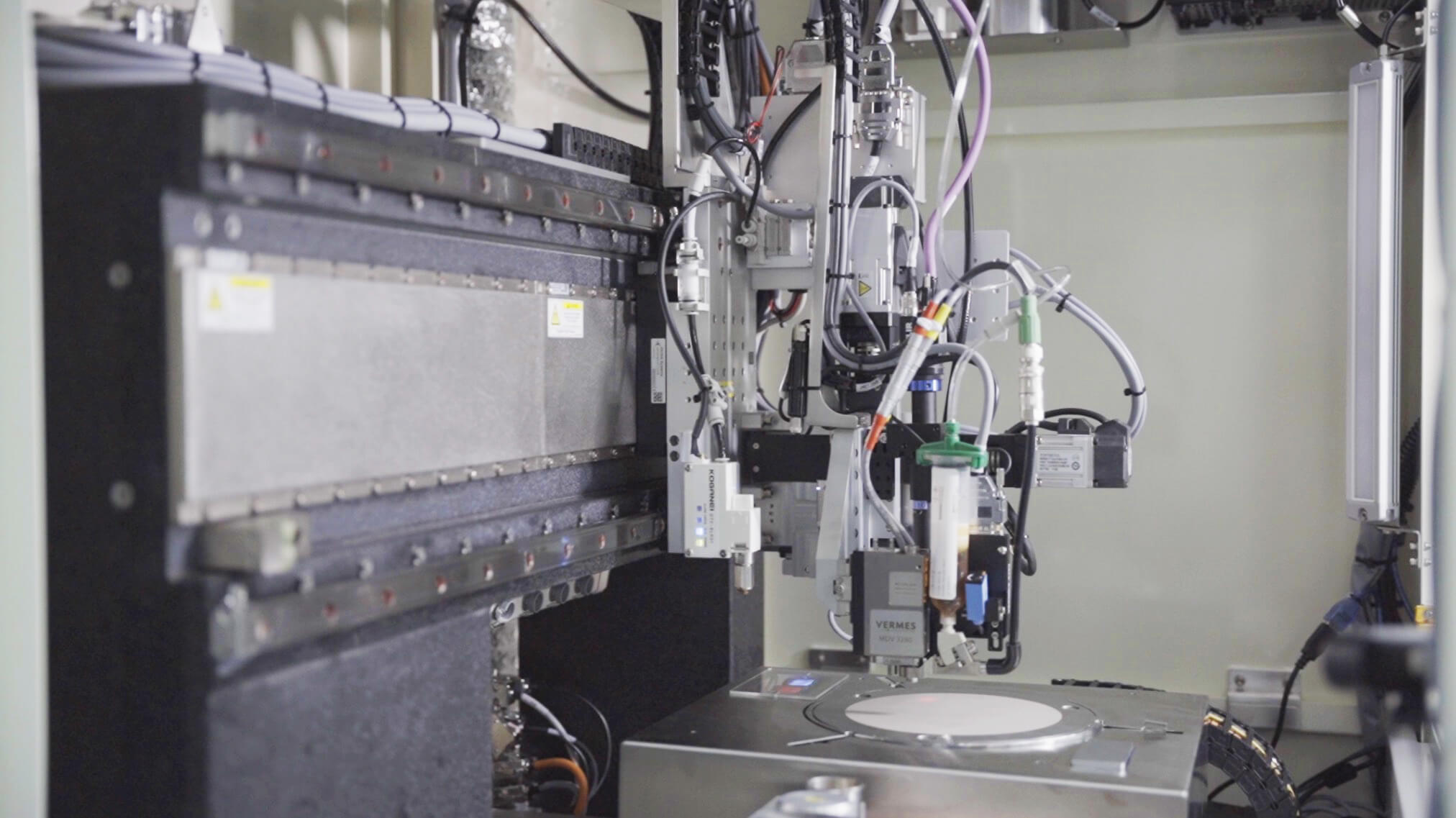

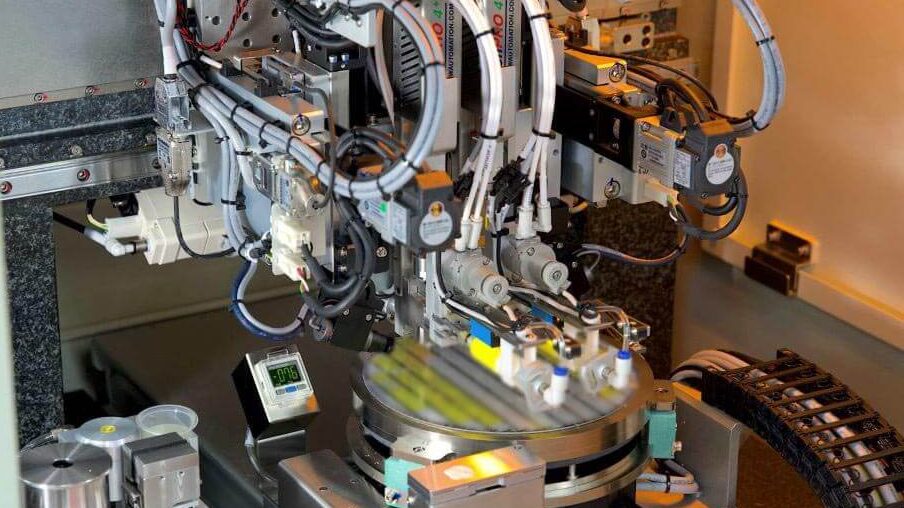

Equipped with high accuracy 4-axis linear/servo motor drive system for XYZ movement and wafer rotary axis

Precise operation of 0.5µm resolution with linear encoder system

Integrated high quality granite base structure for stable operation

Fully automate with our SMEMA-compliant system, configurable in cells or stand-alone platform

PC based control system, operated by NSW advanced dispensing software

Cover 12 inches wafers with our 600mm x 400mm XY-axis system with at least 210mm² working envelope.

Advanced vision camera calibration for wafer fiducial scanning and XY alignment.

Optimize height calibration with our non-contact confocal chromatic sensor for high-reflective and transparent surfaces.

Integrated with fully automatic dispenser’s XYZ offset calibration stage and nozzle cleaning function

Precise dispensed weight control by NSW automatic closed-loop dynamic weight calibration system

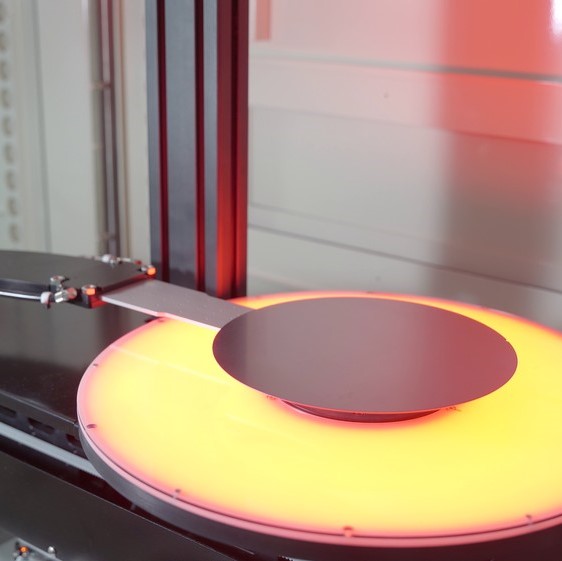

Opt for our system with thermal control at nozzle and work stage for flexible thermal control

Opt for nozzle enlarged-view monitoring system for visual observation during mass production.

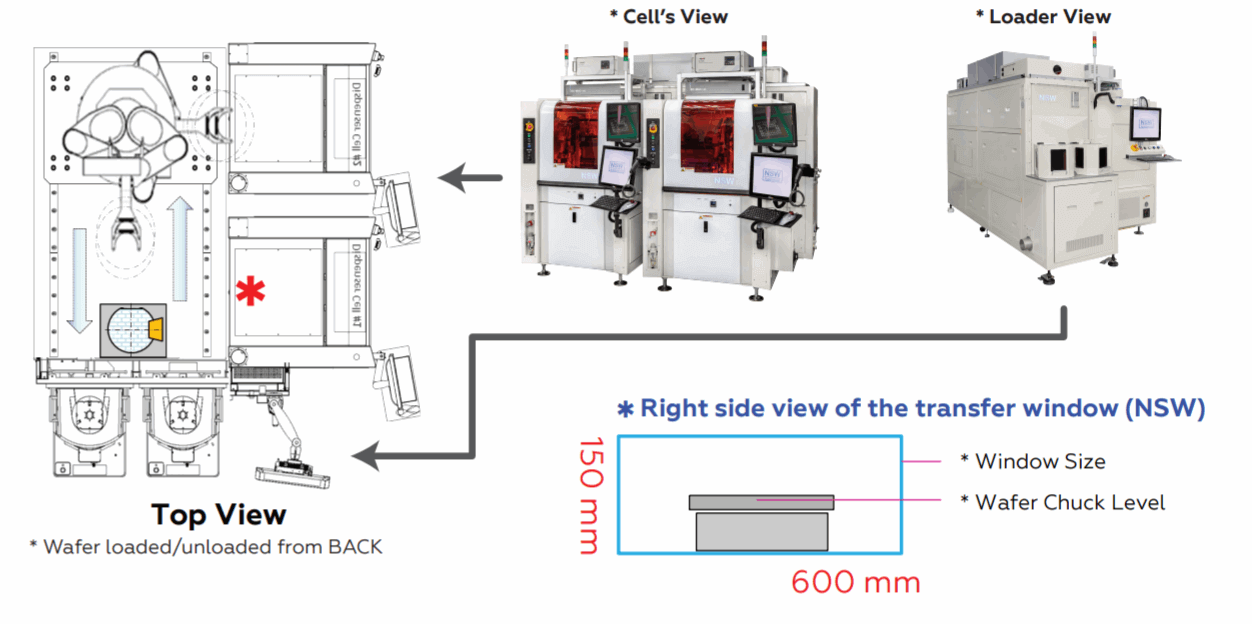

Fully Customizable & Configurable to Multiple Cells Automation System.

Wafer Transfer Sequence to NSW Dispensing Cell

Indexing

Table