Could Precision Dispensing Helps Save Cost in Chip Making?

By NSW Marketing Team. Written on 26 Jan 2023. Last updated on 31 Jan 2023

Precision fluid dispensing is a critical step in the chip making process. It helps to ensure that the right amount of materials are used, resulting in cost savings and quality improvements in the chip making industry. In this article, we will discuss the benefits of precision fluid dispensing and the advancements in precision fluid dispensing systems.

Reducing Waste and Improving Efficiency with PrecisionDispensing

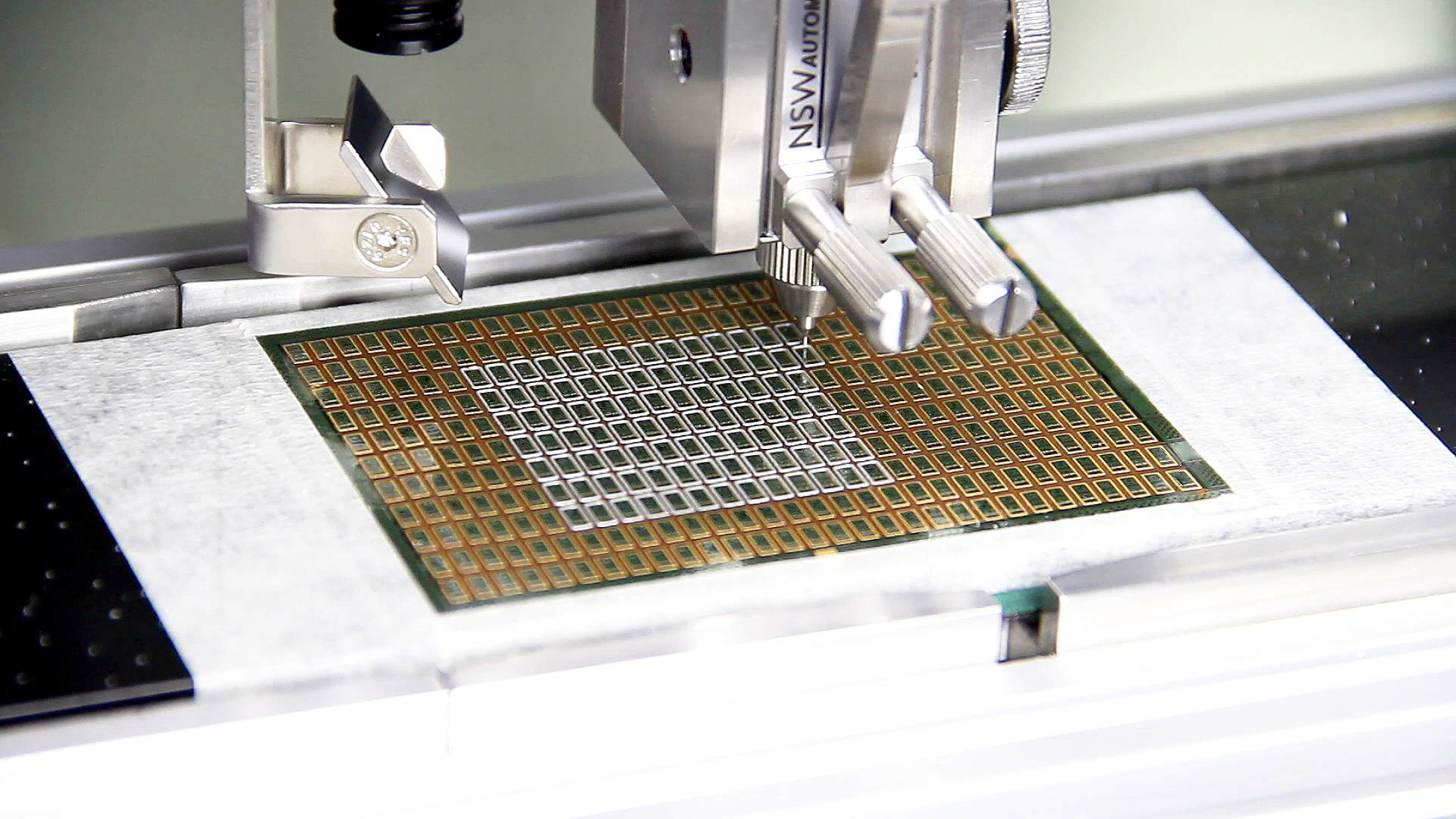

Precision fluid dispensing is the process of dispensing small, precise amounts of fluid materials. This is particularly important in the chip making industry, where accuracy and consistency are crucial for producing high-quality chips. By using precision fluid dispensing, chip manufacturers can reduce waste and improve their overall precision and efficiency.

Cost of Chip Making Industry through Precision Fluid Dispensing

Precision fluid dispensing could help to reduce waste by ensuring that the exact amount of materials needed for the chip-making process is used. This can lead to significant cost savings for manufacturers when a certain fluid type is high-priced. Additionally, precision fluid dispensing can improve efficiency by eliminating the need for costly stencil rework and reducing manual adjustments. This results in lower labour and production costs, especially when producing high-value products in a short amount of time.

In contrast, precision fluid dispensing systems are much more precise and consistent, leading to higher-quality chips and less material waste (if high-value fluids are used). It offers greater flexibility, allowing manufacturers to dispense a wide range of materials simultaneously. This makes precision fluid dispensing a more attractive option for manufacturers compared to stencil screen printing when dealing with high-value fluid.

Quality Improvements in Chip Making Industry with Precision Fluid Dispensing

Precision fluid dispensing is also vital for improving the quality of chips produced. By distributing precise and consistent amounts of materials, manufacturers can ensure that the chips have the same properties and are of the same high quality. This is achieved through optical inspection during production, ensuring that each chip meets the required standards. This is particularly crucial in the semiconductor and chip manufacturing industries, where high-quality chips are essential for producing high-value electronic devices.

Conclusion – Final thoughts

In conclusion, precision fluid dispensing plays a critical role in the chip-making process. While it may not be as cost-effective as stencil solder for distributing low-cost materials such as higher powder size solder paste at larger targets, it can lead to significant cost savings and quality improvements for manufacturers when dispensing high-value fluids. With the advancements in precision fluid dispensing systems, achieving higher accuracy and efficiency is now more achievable.

That’s where we come in – we are one of the leading precision fluid dispensing system manufacturers for chip-making and semiconductor industries. Our systems are designed to provide high precision, reliability, and versatility, making them an ideal option for manufacturers looking to improve their production processes at small/large scales with versatility and flexibility. We offer a wide range of dispensing systems, including solder paste, UV glue, epoxies, and microdispensing applications, to cater to different needs.